Ecommerce Warehousing Systems Transform Supply Chain Efficiency

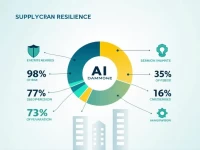

Modern Warehouse Management Systems (WMS) play a critical role in the e-commerce supply chain by enhancing storage efficiency and accuracy through real-time data sharing and intelligent functions. With the application of AI and machine learning, WMS is continually evolving to meet the fast-growing demands of the e-commerce sector.