Postpandemic Supply Chains Prioritize Talent and Agility

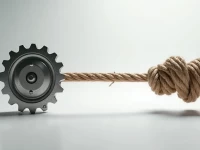

Facing the challenges of the 'new normal' in supply chains, businesses need to move beyond peak season thinking and embrace flexible operations. Upgrading talent strategies to attract, retain, and develop high-quality workforce is crucial. Leveraging data-driven decision-making optimizes labor management. Technology empowers productivity gains. Focusing on employee well-being and creating a safe and healthy work environment are essential. These elements contribute to building a resilient supply chain capable of adapting to changing demands and disruptions, ensuring business continuity and sustainable growth.