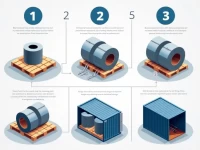

Steel Coil Loading Guide Aims to Prevent Shipping Damage

This article provides a detailed interpretation of the seven key steps for loading coil steel into containers, including the use of dunnage, lateral securing, end coil treatment, wire rope lashing, front and rear wooden supports, full container door display, and single-side door closure display. Through illustrated instructions, it aims to help readers avoid potential risks and ensure the safe transportation of goods. It emphasizes best practices for securing coil steel within containers to prevent shifting and damage during transit, ultimately contributing to cargo security and efficient container shipping.