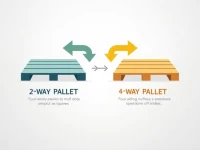

4-Way Pallets Boost Efficiency in Modern Logistics Operations

This article discusses the importance of pallets in logistics, focusing on the differences between 2-Way Pallets and 4-Way Pallets. A 2-Way Pallet allows forklift entry from only two directions, making it less versatile; whereas a 4-Way Pallet can be accessed from all four sides, facilitating more flexible loading and unloading, thus enhancing logistics efficiency. Therefore, understanding the types of pallets is crucial for managing cargo transportation.