Imagine the intricate journey of a package from the moment you click "buy" to its arrival at your doorstep. Behind Amazon's massive logistics network, every second of efficiency matters—not just for speed, but for cost reduction, customer satisfaction, and maintaining market leadership.

Facing surging order volumes and rising consumer expectations for fast, reliable delivery, Amazon is accelerating its logistics network's intelligent transformation. This goes beyond simple automation—it's about building a self-learning, self-optimizing smart logistics ecosystem using cutting-edge technologies.

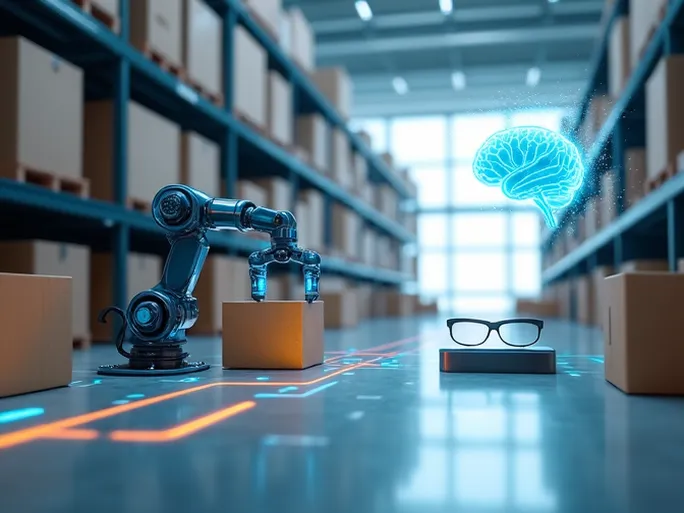

The e-commerce giant recently unveiled three groundbreaking innovations: the Blue Jay multi-arm robotic system , Project Eluna AI operations assistant , and smart delivery glasses . These interconnected technologies represent strategic components of Amazon's intelligent logistics vision—reducing repetitive labor, boosting productivity, and ultimately accelerating deliveries.

Blue Jay: The Multi-Arm Robot Reinventing Warehouse Efficiency

In Amazon's sprawling fulfillment centers, thousands of products are stored, picked, packed and shipped through labor-intensive processes. Blue Jay's integrated robotic system addresses this challenge by coordinating multiple robotic arms to perform material handling tasks simultaneously.

Traditional warehouse workflows require separate workstations for picking, storing and consolidation—forcing employees into repetitive motions that cause fatigue and injuries. Blue Jay consolidates these functions into a single workspace where coordinated robotic arms minimize human movement while optimizing floor space.

Remarkably, Blue Jay progressed from concept to production in just over a year—far faster than Amazon's typical three-year robotics development cycle. This breakthrough leverages digital twin technology, allowing engineers to test dozens of virtual prototypes before physical implementation.

Currently piloting in South Carolina facilities, Blue Jay already handles approximately 75% of inventory items. Amazon anticipates the system will become crucial for same-day delivery centers, further accelerating fulfillment speeds.

Project Eluna: The AI Co-Pilot Optimizing Logistics Decisions

Amazon's logistics network generates oceans of operational data daily. Project Eluna serves as an AI-powered "teammate" that analyzes this information to help managers make smarter decisions—predicting challenges and recommending solutions before issues arise.

Unlike conventional analytics tools, Eluna understands complex operational contexts. When managers ask questions like "Where should we redirect staff to prevent bottlenecks?", the system provides data-driven recommendations based on comprehensive logistics understanding rather than simple statistics.

Initial testing at Tennessee facilities will focus on optimizing sorting during peak holiday seasons. Future applications include ergonomic shift planning and predictive maintenance—analyzing equipment data to foresee failures before they occur.

Smart Delivery Glasses: Hands-Free Navigation for Last-Mile Efficiency

The final delivery mile presents unique challenges—complex routes, hard-to-find addresses, and safety hazards. Amazon's smart glasses provide hands-free navigation and scanning, allowing drivers to focus on their surroundings rather than smartphone screens.

Early prototypes tested by hundreds of drivers already offer turn-by-turn walking directions—particularly valuable in apartment complexes. Future versions will incorporate real-time error detection (like incorrect address placement), low-light adjustments, and pet alerts for enhanced safety.

The Bigger Picture: Amazon's Strategic Logistics Transformation

These innovations collectively address four critical objectives:

1. Capacity Expansion: Automated systems like Blue Jay increase processing capability to handle growing order volumes.

2. Experience Enhancement: Faster, more accurate deliveries improve customer satisfaction.

3. Cost Optimization: Reduced manual labor and better resource utilization lower operational expenses.

4. Competitive Advantage: Superior logistics capabilities reinforce Amazon's market leadership.

Beyond corporate benefits, Amazon's technological advances are reshaping industry standards—accelerating robotics adoption, deepening AI integration, and popularizing wearable logistics tools across the sector.

Challenges and Future Directions

Despite progress, hurdles remain—high robotics costs, evolving AI algorithms, data security concerns, and integration complexities with existing infrastructure. Looking ahead, intelligent logistics will likely evolve toward:

- More perceptive, collaborative robots

- More sophisticated AI decision-support systems

- More comfortable, feature-rich wearable devices

- More interconnected logistics platforms

Amazon's technological investments represent more than corporate upgrades—they're pioneering the next era of logistics, where intelligent systems work seamlessly alongside humans to deliver unprecedented efficiency, safety and customer satisfaction.