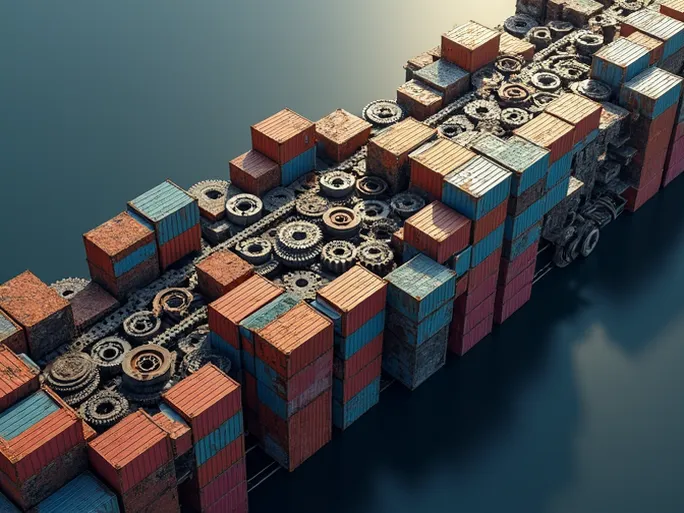

As the global trade landscape undergoes seismic shifts with tariff policies casting long shadows across supply chains, businesses face unprecedented challenges in logistics management. Industry analysis suggests several strategic approaches to navigate this uncertain terrain.

Strategies for Overcoming Tariff Barriers

The evolving international trade environment presents significant challenges for logistics and supply chain operations. Experts recommend several key approaches to mitigate tariff impacts:

- Diversified sourcing channels: Overreliance on single suppliers or countries increases vulnerability to tariff shocks. Companies should actively expand procurement networks to identify alternative suppliers and reduce regional dependencies.

- Supply chain optimization: Strategic reassessment of production and distribution locations, including potential relocation to lower-tariff regions, can significantly reduce costs. Developing regional supply networks enhances resilience against disruptions.

- Enhanced transparency: Advanced technologies like blockchain and IoT enable real-time tracking of goods movement, allowing companies to assess tariff impacts and adjust strategies promptly. Improved visibility supports better risk management.

- Government engagement: Maintaining open communication channels with regulatory bodies ensures timely awareness of policy changes. Participation in industry associations can amplify collective advocacy for favorable trade conditions.

- Pricing strategy adjustments: Rising tariffs may necessitate revised pricing models. Companies might consider selective price increases or operational efficiencies to offset additional costs.

Manufacturing Sector: Challenges and Transformation

Recent industry research reveals manufacturers continue driving product innovation despite multiple challenges including artificial intelligence integration, workforce productivity, and accelerated development cycles.

- AI integration: Artificial intelligence is transforming production paradigms across design, planning, and quality control processes, enabling smarter decision-making and operational efficiencies.

- Workforce development: Enhancing labor productivity through targeted training, technological upgrades, and optimized workflows remains critical. Employee engagement and workplace conditions significantly impact performance outcomes.

- Innovation acceleration: Competitive markets demand rapid innovation cycles. Effective mechanisms for idea generation and swift commercialization, combined with strategic partnerships, fuel technological advancement.

2025: A Year of Disruption and Adaptation

The logistics sector faces heightened uncertainty in 2025, with persistent volatility, unpredictable policy shifts, and imbalanced demand patterns creating complex operational challenges across all transportation modes.

- Persistent volatility: Geopolitical tensions, economic fluctuations, and unexpected disruptions require robust risk management frameworks to maintain supply chain continuity.

- Policy unpredictability: Regulatory changes continue to directly impact logistics operations, necessitating agile strategy adjustments and proactive policy engagement.

- Demand fluctuations: Market variability remains constant, requiring enhanced customer insight and service adaptability, complemented by strategic market diversification.

Industry leaders will need heightened situational awareness, operational flexibility, and strategic confidence to identify opportunities within this challenging environment.