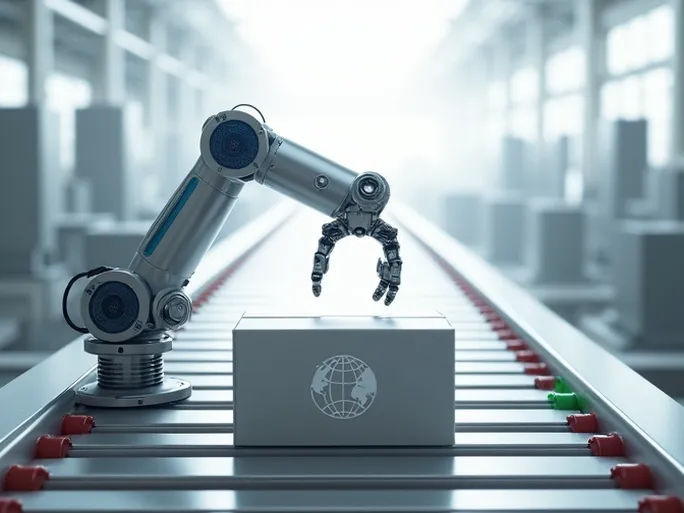

Imagine a factory floor where bustling crowds and deafening machine noise have been replaced by robotic arms working with silent precision—handling materials, assembling components, and operating around the clock. This isn't science fiction; it's today's industrial reality. According to the International Federation of Robotics (IFR), over 4.2 million robots were deployed in global factories by 2024, fundamentally reshaping manufacturing processes. While this automation wave brings unprecedented efficiency, it simultaneously presents both challenges and opportunities for the logistics sector.

The Current State of Robotics: Accelerating Factory Automation

The IFR report clearly demonstrates that global manufacturing is undergoing a robotics-driven transformation. These 4.2 million industrial robots aren't just boosting productivity—they're optimizing workflows and reducing operational costs across industries. From automotive plants to electronics assembly lines and metal fabrication facilities, robots excel at repetitive, hazardous tasks that once required human labor. With technological advancements steadily lowering implementation costs, industry analysts predict continued exponential growth in robotic deployments.

Logistics Under Pressure: Navigating Unprecedented Challenges

For logistics managers, 2025 presents a perfect storm of operational challenges. Persistent economic volatility, shifting trade policies, and uneven demand patterns have created a crisis environment. Compounding these issues are tariff barriers, trucking shortages, rail bottlenecks, and unpredictable ocean freight rates—factors that force temporary logistical fixes while making accurate forecasting nearly impossible. This uncertainty drives up costs and erodes supply chain reliability at precisely the moment when manufacturing automation demands flawless logistics execution.

Strategic Responses: Turning Challenges Into Competitive Advantages

Facing continued turbulence through 2026, logistics operators must embrace transformative solutions:

- Smart Technology Integration: Accelerate adoption of automated guided vehicles (AGVs), warehouse drones, and intelligent inventory systems to improve accuracy and throughput. Leverage AI-powered analytics for route optimization, inventory management, and demand forecasting.

- Collaborative Supply Networks: Develop transparent, integrated partnerships with suppliers and manufacturers. Blockchain technology can enhance traceability and security across complex supply chains.

- Proactive Risk Mitigation: Implement comprehensive risk assessment frameworks addressing geopolitical instability, natural disasters, and market fluctuations. Develop contingency plans to maintain operational continuity.

- Workforce Transformation: Invest in upskilling programs to develop logistics professionals with digital competencies and adaptive problem-solving skills.

As factory automation accelerates globally, logistics providers face a clear imperative: adapt or become obsolete. Companies that strategically implement intelligent systems, foster supply chain collaboration, manage risks effectively, and cultivate next-generation talent will not only survive current disruptions but emerge as industry leaders. The future belongs to organizations that transform these challenges into opportunities for sustainable growth.