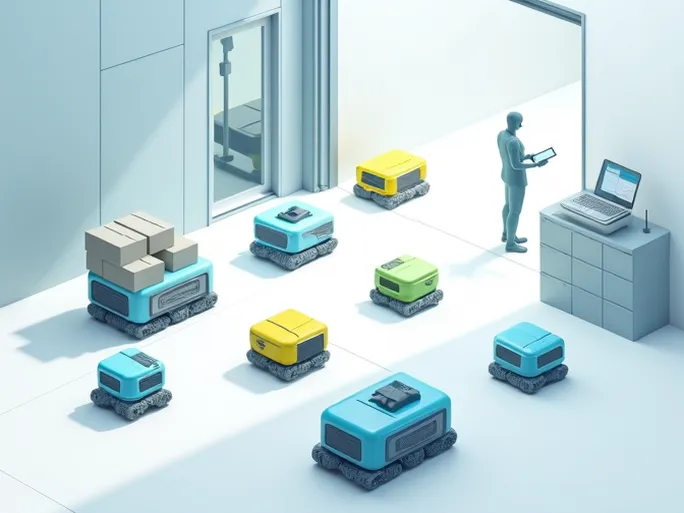

Imagine a warehouse where teams of autonomous mobile robots (AMRs) glide seamlessly through aisles, transporting goods with tireless precision. This robotic workforce represents the future of logistics operations. However, simply deploying more robots doesn't automatically translate to higher efficiency. True operational transformation requires strategic scaling of AMR fleets.

Quality Over Quantity: Rethinking AMR Fleet Sizing

Many companies fall into the trap of equating automation success with robot quantity. In reality, an oversized AMR fleet without proper optimization can underperform compared to a smaller, well-orchestrated robotic workforce. Effective deployment hinges on three critical factors:

Scalability: Can the system rapidly expand robot numbers and personnel during demand surges?

Software Intelligence: Does the control system optimize routing, task allocation, and system integration?

Human-Robot Collaboration: How effectively do robots complement human workers in picking and transport tasks?

AMRs: The Solution to Labor Shortages

With younger generations increasingly reluctant to perform strenuous warehouse work and labor costs rising, AMRs present an ideal solution. John Santagate, VP of Robotics at Körber Supply Chain, observes: "Companies face dual challenges of unfillable positions and rising wages. AMRs reduce both operational costs and labor dependency risks."

By handling repetitive transport tasks, AMRs free human workers for value-added activities like quality control and process improvement. This division of labor also reduces physical strain, boosting job satisfaction and retention rates.

The Human-Robot Productivity Advantage

AMRs aren't replacing humans—they're augmenting them. Traditional picking requires workers to walk miles daily locating items. With AMRs delivering goods directly to pickers, walking distance decreases dramatically while accuracy improves.

Kaitlin Peterson of Locus Robotics notes: "Clients achieve remarkable productivity gains alongside softer benefits like improved worker satisfaction. Reduced walking cuts fatigue by over 50%, while eliminating heavy cart-pushing decreases injury risks."

Strategic Scaling: Measure Before Expanding

Determining optimal fleet size requires analyzing order profiles, existing workflows, facility layouts, and service levels. Santagate advises: "Historical demand patterns, SKU dimensions, and warehouse configuration all influence robot capacity needs. Process adjustments must align with robotic picking environments."

Gradual implementation through pilot projects allows performance evaluation and system refinement before full deployment.

Proven Results: Case Studies in AMR Efficiency

Integrated Supply Network, an automotive tool distributor, achieved 266% higher picking efficiency after integrating Locus Robotics' AMRs with Körber's WMS. Most AMR implementations require weeks—not months—with Robotics-as-a-Service (RaaS) models enabling scalable hardware without upfront capital.

Kenco Group, a 3PL provider, increased picks-per-hour from 30-40 to 120-150 using Locus AMRs. VP Kristi Montgomery emphasizes: "Pre-implementation success metrics are crucial. We carefully defined ours beforehand."

The Human Factor: Designing Effective Collaboration

Vanderlande USA's Colin Thompson highlights often-overlooked human elements: "Automation accomplishes nothing without intelligent human input at every stage." This includes ergonomic workstation design, maintenance training, and performance metrics that encourage healthy competition rather than punishment.

Montgomery recommends phased rollouts: "Pilot implementations rarely reveal all production realities. Gradual introduction allows observation of human adaptation, WMS integration, and necessary process adjustments."

System Integration: Unlocking AMR's Full Potential

Most assisted-picking AMRs require WMS integration for order data. Advanced implementations connect with conveyor systems, packaging lines, or voice systems. Some manufacturers integrate AMRs with MES or ERP solutions, while specialized software like SVT Robotics simplifies multi-system integration.

Zebra Technologies' AMRs demonstrated this flexibility at Bespoke Manufacturing Co., where fixed-position scanning and MES integration automated data collection across 15 robots moving garment components between sewing stations.

Multi-Agent Orchestration: The Next Frontier

As companies deploy diverse AMR types—from pallet movers to case pickers—new software emerges to coordinate mixed fleets. GreyOrange's Akash Gupta explains: "Our platform uses AI-driven 'drivers' to dynamically allocate tasks across robot types and human workers based on real-time conditions."

Körber is developing a Unified Control System to manage heterogeneous robotic environments. Santagate notes: "The challenge lies in creating standardized yet adaptable control platforms for multi-vendor fleets."