Imagine the journey a fashion item takes from design sketches to reaching consumers' hands - how many steps are involved, and how many potential efficiency bottlenecks exist? Fast fashion giant ASOS is attempting to streamline these processes through technology, achieving comprehensive supply chain optimization.

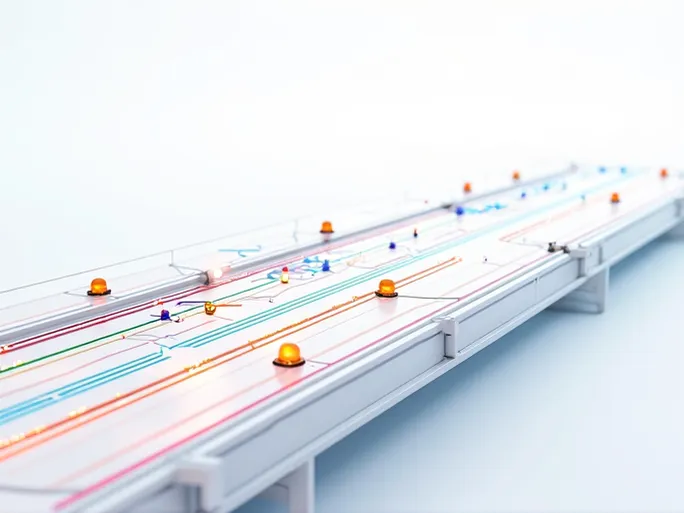

ASOS recently announced the full integration of Celonis' process intelligence platform, aiming to build an end-to-end connected supply chain system. According to Celonis' June 24 press release, the platform will connect ASOS's inbound supply chain, logistics, outbound delivery and returns, as well as product operations, enabling real-time visibility across its entire supply chain. ASOS expects to optimize order fulfillment processes and enhance customer experience through in-depth analysis of the resulting metrics.

Laurence Moore, ASOS Supply Chain Strategy Project Lead, stated: "With Celonis, we've connected our entire supply chain - from intake and inbound to outbound and returns - helping teams break down information silos, simplify processes, reduce costs, and deliver the latest trends to customers faster."

How Celonis Empowers ASOS's Supply Chain

The Celonis platform provides ASOS with powerful data analytics capabilities, enabling the tracking of thousands of SKUs and containers from purchase order initiation to final warehouse placement. The technology can also monitor third-party carrier performance and returns, giving ASOS a comprehensive view of supply chain operations.

Specifically, the Celonis platform delivers significant improvements in these areas:

- Real-time Visibility: By connecting all supply chain segments, Celonis provides ASOS with a real-time, comprehensive operational view, allowing quick identification of potential bottlenecks and issues.

- Process Optimization: The platform analyzes supply chain processes, identifies inefficiencies, and suggests improvements to streamline operations and reduce costs.

- Data-Driven Decisions: Rich analytics help ASOS better understand supply chain performance, enabling smarter decisions regarding inventory management and carrier selection.

- Cross-Department Collaboration: The platform breaks down information silos between departments. For example, merchandising teams can use Celonis data to review product performance, returns, and pricing trends to enhance inventory planning.

Merchandising Transformation: Data-Driven Inventory Management

The merchandising team now leverages Celonis data to gain deep insights into product performance, return rates, and pricing trends. These insights significantly improve inventory planning accuracy, helping ASOS better meet market demand while avoiding overstocking or shortages.

By analyzing historical sales and return data, the merchandising team can predict future trends and adjust inventory levels accordingly. For products with high return rates, they might reduce stock or collaborate with suppliers to improve quality.

Additionally, the team uses Celonis data to optimize pricing strategies. Analyzing price elasticity across products enables more competitive pricing, boosting sales and profit margins.

Future Applications: Expanding Celonis Technology

ASOS is considering applying Celonis technology to more business functions, including order management and warehouse operations. This demonstrates confidence in the platform's value and the desire to further enhance operational efficiency.

Successful implementation across these areas would enable comprehensive supply chain optimization, helping ASOS better meet customer demands, improve satisfaction, and strengthen its competitive position in fast fashion.

Retail's Digital Transformation: Supply Chain Visibility

In an increasingly competitive retail market, supply chain efficiency and flexibility are crucial. More retailers are adopting new technology platforms to improve visibility and leverage data-driven insights to adapt to changing market conditions.

Beyond ASOS, other retailers are exploring supply chain optimization. For example, U.S. supermarket chain Giant Eagle is integrating Manhattan Active Warehouse Management across its distribution network, having already transitioned five of seven distribution centers to this new technology.

Similarly, musical instrument retailer Guitar Center is improving inventory management using Relex Solutions modules to automate replenishment and optimize stock levels.

These cases demonstrate that supply chain visibility has become a critical component of retail's digital transformation. New technology platforms help retailers better understand operations and leverage data to optimize processes, improve efficiency, and enhance competitiveness.

Conclusion: Data-Driven Supply Chains as Competitive Advantage

ASOS's integration of Celonis, along with other retailers' adoption of optimization technologies, clearly illustrates a trend: data-driven supply chain management represents retail's future.

Through real-time data and analytics, retailers gain better operational visibility and make more informed decisions, improving efficiency, reducing costs, and better serving customers.

In an increasingly competitive market, an efficient, flexible, and data-driven supply chain will be key to future success.