In today's rapidly evolving business landscape, warehouse operations face unprecedented challenges. Mounting inventory, worsening labor shortages, and tightening delivery deadlines create complex hurdles for modern enterprises. As automation transitions from luxury to necessity, traditional solutions remain cost-prohibitive for many businesses. The industry urgently needs plug-and-play automation that delivers immediate productivity gains.

The Warehouse Automation Challenge

Operational Pressures

- Labor shortages: Demographic shifts and rising wages make finding qualified warehouse workers increasingly difficult, particularly for repetitive, physically demanding tasks like depalletizing.

- Order volume surges: E-commerce growth strains manual depalletizing capacity beyond sustainable levels.

- Tight delivery windows: Consumer expectations demand faster fulfillment cycles.

- Inventory complexity: Modern warehouses handle diverse product mixes requiring precise management.

- Safety concerns: Manual depalletizing poses injury risks that automation can mitigate.

Automation Opportunities

Warehouse automation presents transformative potential through:

- 30-50% productivity gains

- Reduced labor costs and error rates

- Improved inventory accuracy (99.9%+)

- Enhanced workplace safety

- Greater operational flexibility

The Depalletizing Dilemma

While palletizing has become relatively straightforward to automate, depalletizing presents unique technical challenges:

- Variable product dimensions and packaging

- Irregular pallet configurations

- Dynamic environmental conditions

- Precision handling requirements

Traditional automated depalletizing solutions suffer from:

- 6-12 month deployment timelines

- $500,000+ implementation costs

- Limited adaptability to new SKUs

- Specialized maintenance needs

The DepalOne Solution

Developed through a partnership between Plus One Robotics and beRobox, DepalOne delivers standardized, rapidly deployable depalletizing automation starting at $155,000.

Core Technologies

- PickOne™ Vision System: AI-powered 3D vision with deep learning algorithms

- Paltz Robotic Platform: Modular hardware with configurable end effectors

- Tiered Deployment Options: Collaborative robots (4-week setup, 500 PPH) or industrial robots (8-week setup, 650 PPH)

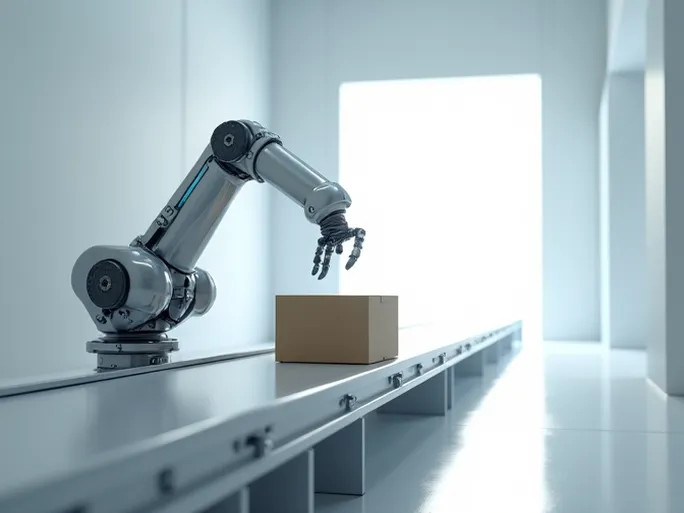

Operational Workflow

- 3D scanning identifies pallet contents

- AI determines optimal grasping strategy

- Robotic arm executes precise item removal

- Products transfer to downstream processes

Industry Applications

DepalOne serves diverse operational needs including:

- Mixed-SKU inbound depalletizing

- Cross-docking operations

- Retail-ready packaging conversion

- Store-specific pallet configurations

Implementation Advantages

Early adopters report:

- 3-6 month ROI timelines

- 85% reduction in depalletizing labor

- 99.5%+ picking accuracy

- Seamless integration with existing WMS

The Future of Warehouse Automation

As artificial intelligence and robotics advance, DepalOne continues evolving with:

- Enhanced computer vision capabilities

- Improved grasping adaptability

- Lower total cost of ownership

- Tighter ERP/WMS integration

This innovative solution represents a significant leap forward in making industrial-grade automation accessible to mid-market operations, potentially reshaping warehouse productivity standards across multiple industries.