Imagine a nearly 3-million-square-foot warehouse where hundreds of robots capable of lifting 1,500-pound loads work alongside thousands of employees to process tens of thousands of orders daily. This isn't a scene from a sci-fi movie but Amazon's newly opened robotics fulfillment center in Charlton, Massachusetts. More than just a warehouse, this facility represents a powerful engine in Amazon's logistics system upgrade, marking a significant step forward in automation and efficiency.

Strategic Expansion: Strengthening Massachusetts as a Smart Logistics Hub

Amazon's investment in Massachusetts has been substantial, with the Charlton robotics fulfillment center serving as the latest milestone. Since 2010, the company has invested over $23 billion in the state, building an extensive logistics network that includes eight fulfillment and sortation centers, 17 delivery stations, and one Prime Now facility.

The new Charlton center, representing an investment exceeding $300 million, stands as Amazon's largest single investment in Massachusetts to date. This demonstrates both confidence in the region's economic potential and commitment to smart logistics innovation.

Key investment highlights:

- Massive scale: The 2.8-million-square-foot facility spans an area equivalent to dozens of football fields, capable of housing vast product inventories and advanced automation equipment.

- Substantial funding: The $300+ million investment covers not just infrastructure but also cutting-edge robotics technology to ensure operational efficiency and quality.

- Strategic importance: As Amazon's largest Massachusetts facility, the Charlton center will serve as a critical logistics hub for the region and the broader Northeast U.S., enhancing delivery speeds and service levels.

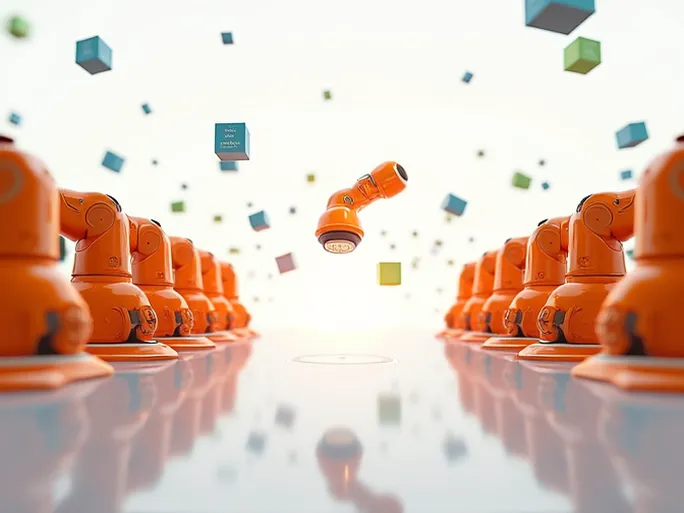

Technological Edge: Robotic Workforce Transforming Logistics Efficiency

The Charlton center's competitive advantage lies in its sophisticated robotic systems. These aren't simple automated machines but intelligent assistants equipped with advanced sensors, artificial intelligence, and machine learning algorithms capable of autonomously performing complex tasks.

Key robotic technologies deployed:

- Transport robots: Hundreds of units can effortlessly lift and move 1,500-pound loads to designated locations, significantly reducing manual handling requirements.

- Picking robots: Amazon is actively developing and deploying various picking robots like Vulcan, which features advanced tactile sensors for precise product identification and handling.

- Conveyance robots: Models like Tipper automate package transfer from carts to conveyor belts, minimizing human intervention and accelerating throughput.

Technological benefits:

- Enhanced efficiency: Robots operate continuously, dramatically improving processing speeds and order turnaround times.

- Improved accuracy: Automated systems precisely identify and handle products, reducing human error in order fulfillment.

- Increased safety: Robots assume hazardous and physically demanding tasks, lowering workplace injury risks.

Operational Model: Human-Robot Collaboration for Optimal Performance

The Charlton facility doesn't rely exclusively on automation but implements a collaborative model combining robotic efficiency with human flexibility. Over 1,000 employees work alongside robots to complete order processing, inventory management, and customer service tasks.

Collaboration framework:

- Task specialization: Robots handle repetitive, high-intensity work like transport and picking, while humans focus on tasks requiring judgment, creativity, and communication.

- Integrated workflow: Both systems operate in shared spaces, coordinated through intelligent management platforms.

- Continuous improvement: Amazon refines collaboration protocols through data analysis and feedback loops to optimize overall efficiency.

Inventory Capacity: Massive Product Selection for Diverse Demand

The facility maintains an inventory exceeding 32 million items across categories including books, electronics, toys, and home goods. Amazon employs intelligent inventory management systems to monitor stock levels, predict demand fluctuations, and ensure product availability while preventing shortages or overstocking.

Inventory management strategies:

- Predictive analytics: Leveraging big data and machine learning to anticipate customer needs and optimize stock levels.

- Dynamic adjustment: Continuously refining product mix based on market trends and sales performance.

- Space optimization: Implementing advanced storage solutions like automated vertical warehouses to maximize density.

Future Outlook: Advancing Innovation in Smart Logistics

The Charlton center represents just one phase in Amazon's smart logistics evolution. The company continues investing heavily in robotics and automation, while developing new operational models to lead industry transformation. Additional robotic fulfillment centers are underway in Virginia and North Carolina to expand the automated logistics network.

Development priorities:

- Advanced robotics: Developing more intelligent, adaptable robots capable of handling complex environments and tasks.

- Greater automation: Expanding automated processes to minimize manual intervention across logistics operations.

- Ecosystem integration: Building comprehensive smart logistics networks connecting suppliers, distributors, and customers for optimized supply chains.

The Charlton robotics fulfillment center not only enhances Amazon's operational capabilities but also establishes new benchmarks for the logistics sector. As technology progresses, smart logistics will increasingly define industry standards, delivering more efficient and convenient consumer experiences.