Many e-commerce sellers and international traders face a common challenge: packages that are lightweight but large in volume, resulting in unexpectedly high shipping fees that eat into profit margins. This article examines how dimensional weight calculations work for international shipments and provides comprehensive strategies to optimize packaging, select cost-effective shipping methods, and implement smart billing approaches.

Understanding Dimensional Weight Calculations

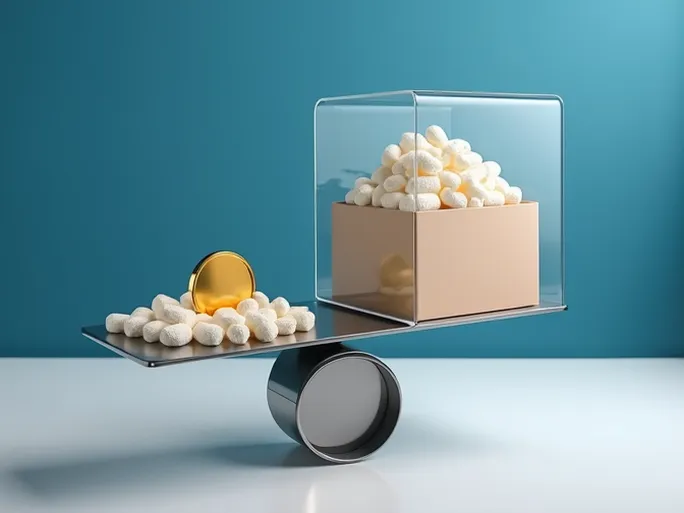

Dimensional weight (also called volumetric weight) is a pricing technique used by couriers to account for the space a package occupies. When a package's volume-to-weight ratio exceeds certain thresholds, carriers charge based on dimensional weight rather than actual weight.

Major Commercial Carriers (DHL/UPS/FedEx/TNT)

- Standard formula: Dimensional weight (kg) = Length × Width × Height (cm) ÷ 5000

- Billing rule: The greater of dimensional weight or actual weight becomes the chargeable weight

- Rounding: Typically rounded up to the next whole kilogram (e.g., 4.1kg becomes 5kg)

Example: A 3kg package measuring 40×30×20cm would have a dimensional weight of (40×30×20)÷5000 = 4.8kg. The carrier would charge for 5kg.

Economy and Heavyweight Services

- Some budget services may use ÷6000 divisors instead of ÷5000

- Always verify calculation methods with carriers to avoid billing disputes

Postal and Specialized Services

- EMS: Often uses ÷6000 divisor; some destinations ignore dimensional weight entirely

- Cross-border services: Vary between ÷5000 and ÷6000; some exempt small parcels from dimensional weight

Special Cases

- Irregular shapes: Use measurements of the smallest rectangular box that could contain the item

- Consolidated shipments: Calculate total volume before dividing by the divisor, not individual packages

- Inch measurements: Dimensional weight (kg) = L×W×H (inches) ÷ 305; (lbs) = L×W×H ÷ 139

Cost-Saving Strategies for Bulky Shipments

1. Package Volume Reduction

- Vacuum compression: Reduce volume by 50-70% for compressible items like clothing

- Streamlined packaging: Replace manufacturer packaging with slim, sturdy boxes

- Efficient filling: Use lightweight void fill (bubble wrap, air pillows) instead of bulky foam

- Optimal arrangement: Nest items strategically to minimize empty space

- Regular shapes: Avoid protrusions that increase measured dimensions

2. Strategic Carrier Selection

- Prefer ÷6000 services: Can reduce dimensional weight by ~17% compared to ÷5000

- Air freight consolidation: Negotiate 50-80% dimensional weight discounts for bulk shipments

- Route optimization: Choose services that include remote area delivery to avoid surcharges

3. Smart Shipping Tactics

- Consolidation: Combine multiple small packages to reduce base rate charges

- Weight optimization: Understand carrier rounding rules (e.g., 0.5kg increments below 21kg)

- Pre-shipment verification: Confirm dimensional weight policies before dispatch

4. Compliance and Fee Management

- Accurate declarations: Prevent customs delays that may trigger remeasurement

- Cost forecasting: Estimate all potential fees (duties, surcharges) upfront

- Seasonal planning: Avoid peak periods when handling fees may apply

Practical Examples and Common Pitfalls

Case study: A 5kg package measuring 50×40×30cm would have:

- 12kg chargeable weight at ÷5000

- 10kg at ÷6000 (17% savings)

- 8.5kg with 50% dimensional weight discount (29% savings)

Avoid these mistakes:

- Incorrect measurements including packaging protrusions

- Address errors causing redelivery fees

- Choosing budget services with unfavorable dimensional weight policies

Effective management of dimensional weight requires a multifaceted approach combining packaging optimization, carrier selection, and strategic shipping practices. By implementing these techniques, businesses can significantly reduce international shipping costs and improve profitability.