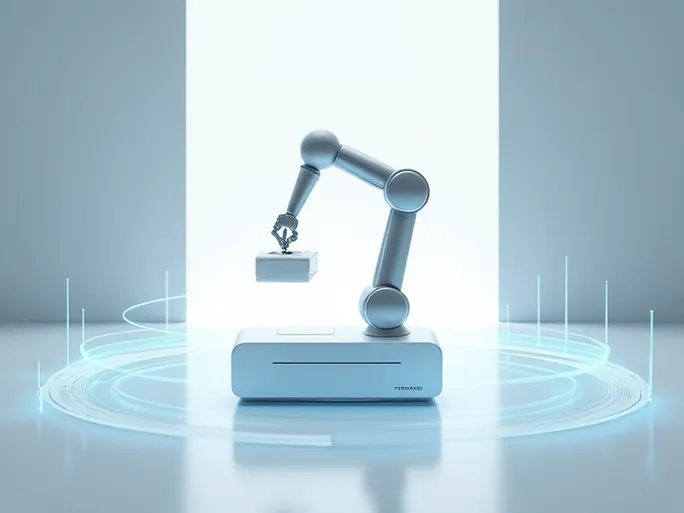

Imagine your warehouse no longer as a maze of stacked goods, but as an efficiently organized, smart operational center. Teams of robots navigate the space, precisely executing sorting, transportation, and storage tasks—dramatically improving operational efficiency while reducing labor costs. This isn't some distant future scenario, but rather today's reality.

The Rise of Industrial Robotics

As robotics technology permeates industries at unprecedented speed—particularly in logistics—businesses face both opportunities and challenges. Gartner analysts report approximately 34 different robot types currently deployed across factories and warehouses worldwide, signaling that robotic integration will soon become indispensable for competitive operations.

2023 Robotics Trends: Measurable Performance and Seamless Integration

This year's robotics development focuses sharply on quantifiable performance metrics and system integration. Enterprises now prioritize operational impact over mere robot quantities, demanding solutions that combine robust performance with flexible configurations, simplified maintenance, and comprehensive support services.

Warehouse Automation: An Inevitable Transformation

The surge of robotics in warehouse operations reflects irreversible market forces. E-commerce expansion and rising consumer expectations for logistics efficiency render traditional management models obsolete. Robotic technology provides the necessary capabilities to handle escalating order volumes and evolving customer requirements.

Scaling Mobile Robotics: Critical Success Factors

Autonomous Mobile Robots (AMRs) gain popularity through their flexibility and deployment advantages. However, successful large-scale implementation requires careful consideration of operational needs, environmental factors, and technical readiness—including proper robot selection, detailed deployment planning, staff training, and maintenance protocols.

Autonomous Forklifts: The Next Frontier in Material Handling

Emerging as game-changers in logistics, self-navigating forklifts operate without human intervention—identifying obstacles and completing transfers autonomously. These systems reduce labor costs while improving safety and efficiency. As technology matures and costs decline, broader adoption appears imminent.

Material Handling Robotics: Essential Knowledge

As the most widely implemented logistics robots, material handling systems perform diverse tasks including sorting, transporting, palletizing, and packaging. Understanding their structural designs, operational principles, control methods, sensor technologies, and safety protocols proves essential for effective implementation.

System Integration: The Critical Next Step

Robot acquisition represents only the beginning—successful integration with existing infrastructure determines ultimate effectiveness. This complex process often requires specialized technical expertise, prompting many organizations to partner with experienced integrators for solution development, testing, and optimization.

Case Study: Medline's Robotics Success Story

Medical supplier Medline demonstrates robotics' transformative potential through its warehouse automation initiative. By implementing mobile robots, the company achieved significant efficiency gains—reducing labor costs while accelerating order processing and improving employee working conditions.

The robotics revolution continues reshaping logistics operations. Forward-thinking organizations must actively engage with this transformation—understanding technological developments, selecting appropriate solutions, and aligning implementations with strategic objectives to maintain competitive advantage.