Executive Summary

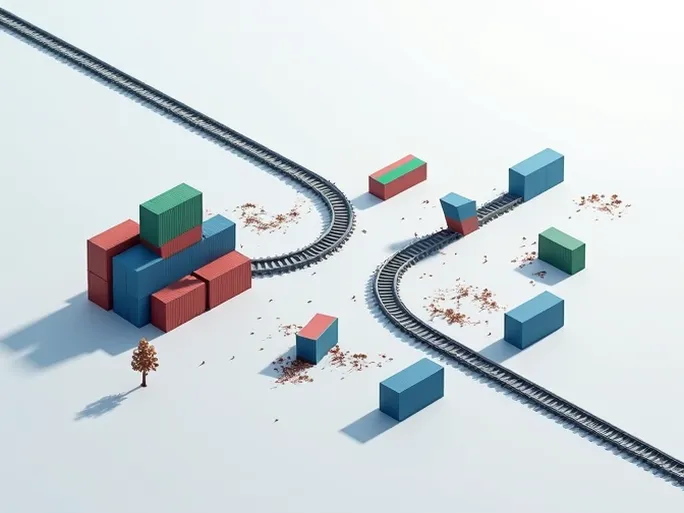

Global supply chains face unprecedented pressure from port congestion, inland transportation bottlenecks, and demand fluctuations, resulting in significant delays and rising costs. The recent decision by Union Pacific Railroad (UP) to temporarily suspend rail service from West Coast ports to Chicago's Global IV hub further highlights the fragility of current supply networks. This analysis examines the causes, impacts, and underlying systemic issues revealed by this disruption while proposing solutions for building more resilient supply chains.

1. Introduction: Global Supply Chain Challenges and Rail's Critical Role

Modern supply chains constitute complex networks connecting producers with consumers across procurement, manufacturing, logistics, and distribution. Recent challenges include:

- Pandemic disruptions: COVID-19 caused production halts, demand volatility, labor shortages, and transportation constraints.

- Geopolitical risks: Trade conflicts and regional instability have forced supply chain reevaluations.

- Climate impacts: Extreme weather events disrupt agricultural output and infrastructure.

- Digital transformation: Emerging technologies require redesigned supply chain processes.

Within this context, U.S. rail networks face their own challenges:

- Aging infrastructure requiring modernization

- Insufficient capacity for growing freight demand

- Persistent labor shortages

- Operational changes from Precision Scheduled Railroading (PSR)

2. The Union Pacific Service Suspension: Causes and Context

2.1 Service Disruption Details

UP implemented a one-week suspension of West Coast-to-Chicago rail services to alleviate congestion at the Global IV intermodal facility, affecting:

- Primary routes from Los Angeles/Long Beach ports to Chicago

- Consumer goods, industrial products, and agricultural commodities

2.2 Root Cause Analysis

The Global IV congestion stemmed from:

- Container backlogs exceeding yard capacity

- Chassis shortages slowing equipment turnover

- Insufficient labor for terminal operations

- Infrastructure limitations preventing chassis-free container handling

2.3 Operational Model Constraints

Global IV's chassis-dependent model creates inherent vulnerabilities. Without adequate chassis supplies or alternative handling equipment like straddle carriers, the facility cannot maintain fluid operations during peak volumes.

2.4 Precision Scheduled Railroading Impacts

While PSR improves operational efficiency through lean resource allocation, it reduces system resilience by:

- Minimizing buffer capacity for disruptions

- Increasing congestion risks from tightly scheduled networks

- Limiting service flexibility for customer needs

3. Impact Assessment

3.1 West Coast Port Consequences

The suspension exacerbated existing port congestion, with container dwell times approaching five days at Los Angeles terminals - delaying goods movement and increasing storage costs.

3.2 Inland Market Effects

Midwestern businesses faced material shortages and production delays, while consumers encountered potential price increases from elevated transportation costs.

3.3 Enterprise-Level Disruptions

Companies experienced:

- Extended lead times and missed deliveries

- Inventory imbalances and excess carrying costs

- Margin compression from rising logistics expenses

4. Systemic Vulnerabilities Exposed

The event revealed critical weaknesses:

- Overreliance on single transportation modes

- Insufficient redundancy across networks

- Information silos limiting visibility

- Fragmented coordination between stakeholders

- Uneven digital transformation progress

5. Building Supply Chain Resilience

Key recommendations include:

- Transportation diversification: Develop multimodal alternatives

- Strategic redundancy: Maintain buffer inventories and resources

- Enhanced visibility: Implement IoT and data-sharing platforms

- Collaborative planning: Strengthen partner coordination

- Infrastructure investment: Modernize ports and rail networks

- Equipment optimization: Improve chassis management

- Risk management: Develop contingency frameworks

6. Corporate Case Studies

Nike: Digital supply chain implementation enabled real-time monitoring and predictive analytics.

Intel: Geographic diversification reduced single-point failure risks.

P&G: Enhanced partner collaboration improved responsiveness.

7. Conclusion

The UP service suspension exemplifies systemic supply chain fragility in an interconnected global economy. Building resilience requires coordinated efforts across private and public sectors to withstand future disruptions.

8. Future Research Directions

- Resilience measurement frameworks

- Digital technology applications

- Risk modeling methodologies

- Collaboration mechanisms

- Policy development