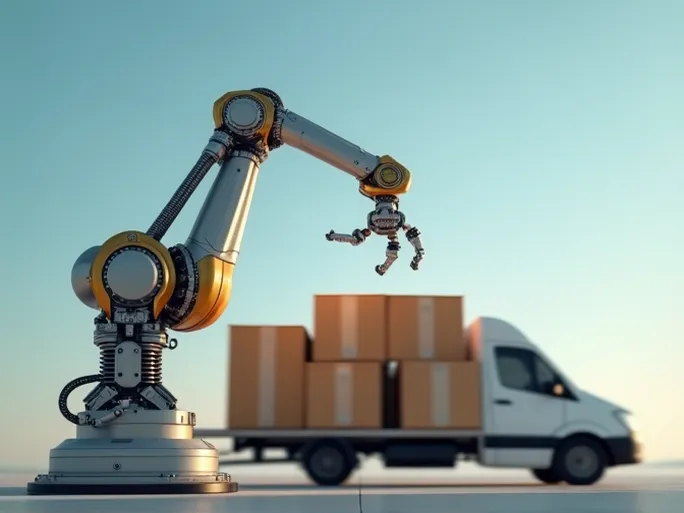

Imagine your warehouse entrance: stacks of shipping containers, lines of trucks, exhausted unloading crews struggling with inefficiency, rising costs, and constant safety hazards. This scenario represents the daily reality for many logistics companies. Rather than lamenting these challenges, forward-thinking businesses are turning to technological solutions. Mobile robots are quietly transforming unloading operations, emerging as the secret weapon against logistical bottlenecks.

Why Automation Matters in Unloading Operations

The benefits of automated unloading systems, particularly those utilizing mobile robots, extend far beyond simple labor replacement. First, these systems address critical workforce shortages. In an era where recruiting for physically demanding jobs grows increasingly difficult—especially among younger workers—robots offer 24/7 operational capability without fatigue.

Second, automation delivers significant cost efficiencies. While initial investments may appear substantial, long-term savings emerge through reduced labor expenses, increased throughput, and minimized product damage. Most importantly, robotic systems dramatically improve workplace safety. Unloading operations rank among the most hazardous warehouse activities, where human workers face constant risks of injury. Robots assume these dangerous tasks, creating safer work environments.

Essential Capabilities for Unloading Robots

Effective mobile unloading robots require several critical components:

- Advanced Perception Systems: Robots must accurately identify diverse cargo types, including variations in size, shape, and weight, while precisely determining position and orientation. This typically requires multimodal sensor integration combining vision systems, LiDAR, and other detection technologies.

- Dynamic Mobility: Navigation in confined spaces demands exceptional maneuverability to avoid obstacles and reach precise destinations. Sophisticated motion control and real-time pathfinding algorithms enable this flexibility.

- Adaptive Manipulation: Safe, reliable cargo handling requires context-aware gripping mechanisms. Modern systems employ intelligent end-effectors—from articulated claws to vacuum-based solutions—that automatically adjust to load characteristics.

- Cognitive Control Architecture: Centralized intelligence coordinates autonomous operation, optimizing workflow through advanced computation. Artificial intelligence algorithms enable collaborative operation with other warehouse systems while continuously improving performance.

Implementing Robotic Unloading Solutions

Successful deployment of automated unloading systems requires methodical planning:

1. Needs Assessment: Companies must first quantify operational requirements—including daily throughput, cargo diversity, and facility constraints—to determine appropriate robotic configurations.

2. System Design: Engineers then develop customized solutions specifying robot quantities, spatial arrangements, and workflow integration to maximize efficiency within existing infrastructure.

3. Enterprise Integration: Seamless connectivity with warehouse management (WMS) and transportation management (TMS) systems ensures synchronized data flow across supply chain operations.

4. Validation Testing: Rigorous pre-deployment trials verify system reliability under simulated real-world conditions, allowing for performance optimization.

5. Workforce Training: Comprehensive operator education programs ensure staff proficiency in robotic supervision, maintenance protocols, and emergency procedures.

The transition to robotic unloading represents an inevitable evolution in logistics management. Beyond solving immediate operational challenges, automation positions companies for future competitiveness in an increasingly technology-driven industry landscape.