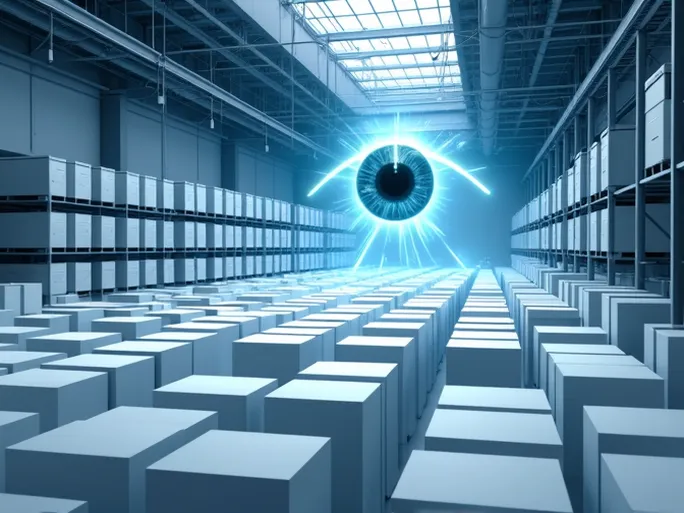

Imagine a warehouse no longer as a static space filled with goods, but as an intelligent entity with "eyes" and a "brain." Every item, every forklift, and every employee's movement is captured in real time, analyzed, and transformed into actionable insights to optimize operations. This is not science fiction—it’s the revolution being driven by edge computing and AI vision technology in the logistics industry.

Traditional logistics management relies on manual record-keeping and delayed data analysis, often leading to inefficiencies, high costs, and safety risks. However, with the proliferation of Internet of Things (IoT) technology and advancements in artificial intelligence (AI) algorithms, intelligent vision systems are reshaping the operational models of transportation, warehousing, and logistics companies in unprecedented ways. This article explores how AI-driven vision technology and edge computing provide real-time insights, helping businesses enhance efficiency, reduce costs, and improve services.

AI Vision and Edge Computing: The "Eyes" and "Brain" of Logistics

AI vision systems, as the name suggests, give machines the ability to "see." Using cameras, sensors, and other devices, these systems capture image and video data, then analyze it with deep learning algorithms to identify objects, detect anomalies, and track movement. Edge computing, meanwhile, shifts data processing and analysis from the cloud to devices closer to the data source—such as on-site servers or smart cameras in warehouses. This distributed computing model significantly reduces latency, improves response times, and alleviates the computational burden on the cloud.

In logistics, the combination of AI vision and edge computing enables:

- Smart Monitoring and Safety Management: By continuously observing warehouse and transportation activities, AI vision systems can automatically detect violations and safety hazards, such as employees not wearing helmets or forklifts exceeding speed limits. When anomalies are identified, the system immediately alerts personnel, reducing accident risks and ensuring workplace safety.

- Automated Inventory Tracking: Traditional inventory counts are labor-intensive, time-consuming, and prone to errors. AI vision systems scan barcodes or QR codes to identify product types, quantities, and locations, updating inventory records in real time. This improves accuracy, prevents overstocking or shortages, and eliminates manual inefficiencies.

- Optimized Loading and Unloading: AI vision systems analyze the dimensions, weight, and shape of goods to plan optimal loading sequences, guiding forklift operators. They can also detect damaged items early, minimizing losses. These optimizations shorten processing times and boost throughput.

- Route and Transportation Efficiency: During transit, AI vision monitors vehicle conditions, traffic patterns, and road congestion. By processing this data, the system dynamically adjusts routes to avoid delays, reducing fuel consumption and emissions while improving delivery times.

Industry Pioneers: Success Stories in AI and Edge Computing

Leading logistics companies are already leveraging these technologies with measurable results:

- Enhanced Workplace Safety: A major e-commerce company uses AI vision to monitor warehouse compliance, such as proper forklift operation and safety gear usage. Real-time analytics have reduced accidents and improved training protocols.

- Faster Port Operations: A maritime logistics firm deployed AI to scan container IDs, dimensions, and weights, automating loading plans. This cut unloading times by 20%, reducing ship wait times and operational costs.

- Streamlined Package Sorting: A delivery company automated parcel sorting with AI vision, accelerating processing while lowering labor expenses. The system also tracks shipments in real time, resolving issues like lost or damaged items to enhance customer satisfaction.

Rapid Deployment: Unlocking the Potential of Existing Hardware

Many businesses assume AI and edge computing require heavy upfront investment. However, existing hardware—such as surveillance cameras and servers—can often be repurposed with software upgrades. For example:

- Retrofitting cameras with AI analytics software enables instant smart monitoring.

- Upgrading on-site servers to edge-computing nodes allows local data processing.

Such adaptations minimize deployment costs and accelerate digital transformation.

Conclusion: Embracing the Future of Logistics

AI vision and edge computing are redefining logistics operations. By equipping machines with the ability to see and analyze, businesses gain real-time oversight, automate workflows, and optimize efficiency. In an era of rapid technological advancement, adopting these tools is no longer optional—it’s the key to staying competitive.