As e-commerce platforms launch increasingly aggressive promotional campaigns, generating tidal waves of orders, logistics packaging operations face unprecedented pressure. Slow packaging speeds, rising labor costs, and stubbornly high package damage rates have become critical bottlenecks constraining business growth. The question facing retailers: How to break through these constraints and gain competitive advantage?

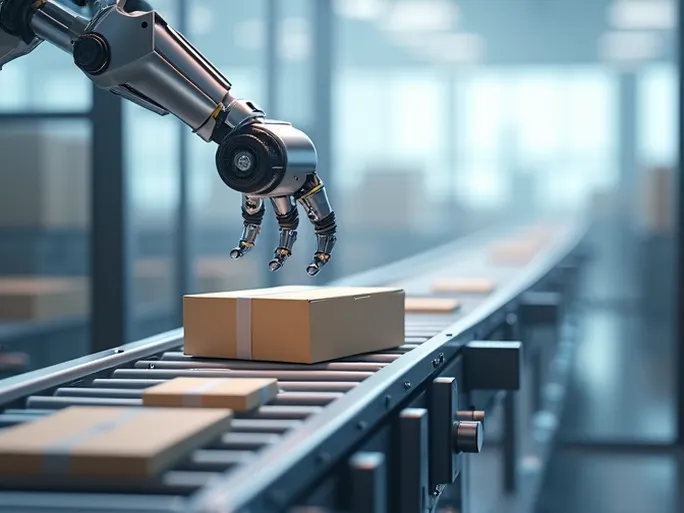

Forward-thinking logistics providers now recognize the strategic importance of this "last mile" in fulfillment operations. They're actively adopting emerging packaging technologies that deliver efficiency, cost savings, and environmental benefits—key requirements in today's automated fulfillment landscape where reducing errors and enhancing customer experience are paramount.

The Packaging Revolution: Addressing Core Industry Challenges

Modern supply chains are undergoing profound transformations in packaging and shipping operations. Traditional methods struggle to keep pace with surging order volumes and customer expectations for rapid delivery. Compounding these pressures are rising labor costs and shortages of skilled workers.

Inefficient packaging creates a double penalty—inflating transportation expenses while increasing product damage rates that erode customer satisfaction. This perfect storm has created urgent demand for solutions that simultaneously boost efficiency, reduce costs, minimize waste, and elevate the customer experience.

The Automated Packaging Advantage

Automated packaging systems address these challenges through precision-engineered technology that optimizes workflows, minimizes human intervention, and enhances speed and accuracy throughout the packaging process.

Leading this transformation is Quadient's CVP automated packaging solution, featuring two flagship products: the CVP Impack and CVP Everest systems. These solutions revolutionize order fulfillment by dramatically reducing labor requirements and optimizing package dimensions across diverse industries.

The CVP systems perform fully automated measurement, construction, sealing, weighing, and labeling for both single-item and multi-item orders. Their intelligent design accommodates both hard and soft goods in perfectly sized packaging, often eliminating filler material requirements entirely. Designed for seamless integration into existing fulfillment operations, these systems deliver exceptional reliability and serviceability.

CVP Impack: Compact Efficiency for Growing Businesses

Engineered for small-to-midsize enterprises and e-commerce operations, the space-efficient CVP Impack features modular design for flexible configuration. Its standout feature: single-operator functionality that handles the entire packaging process.

The system automatically measures products, selects optimal packaging, and executes precision cutting, folding, sealing, and labeling—achieving blistering speeds of 500 packages per hour while dramatically reducing labor costs.

CVP Everest: Industrial-Grade Packaging Performance

For large enterprises and logistics hubs, the CVP Everest delivers next-level performance through advanced robotics and vision recognition systems. Processing up to 1,100 packages hourly—more than double the Impack's capacity—this solution handles diverse product configurations with equal precision.

The Everest system incorporates intelligent inventory management that tracks packaging material usage in real time, preventing waste and optimizing stock levels.

Competitive Edge Through Packaging Innovation

Quadient's solutions deliver measurable advantages where they matter most:

Throughput: The CVP Impack processes 500 packages hourly with single-operator efficiency, while the Everest achieves 1,100 packages with just two operators—critical capacity for peak demand periods.

Cost Reduction: Automation slashes labor expenses while optimized packaging minimizes material waste and transportation costs.

Quality Assurance: Precision packaging reduces product damage, while consistent presentation enhances brand perception.

Customer Satisfaction: Faster, more reliable fulfillment directly improves customer experience and loyalty.

Strategic Packaging: An Overlooked Competitive Weapon

In today's hyper-competitive markets, packaging operations have evolved from cost centers to strategic differentiators. Automated solutions serve as essential risk management tools during peak seasons, labor shortages, or supply chain disruptions.

For e-commerce particularly, where delivery speed directly impacts conversion and retention, automated packaging provides the dual advantage of accelerated fulfillment and reduced shipping costs—a combination that can determine market leadership.

The Future of Packaging Automation

As businesses confront labor shortages, rising costs, and escalating customer expectations, automated packaging emerges as a transformative solution. These systems address multiple challenges simultaneously—reducing labor dependence, controlling costs, enabling customization, and boosting operational efficiency.

For enterprises committed to maintaining competitive advantage, investment in packaging automation represents both immediate operational improvement and long-term strategic positioning. As technology advances, these systems will grow increasingly intelligent, adaptable, and personalized—delivering ever-greater value across the supply chain.

Quadient's CVP solutions exemplify this evolution, offering businesses a clear pathway from inefficient manual processes to automated, optimized packaging operations. In markets where every efficiency and customer impression counts, such transformation isn't just advantageous—it's essential for sustained success.