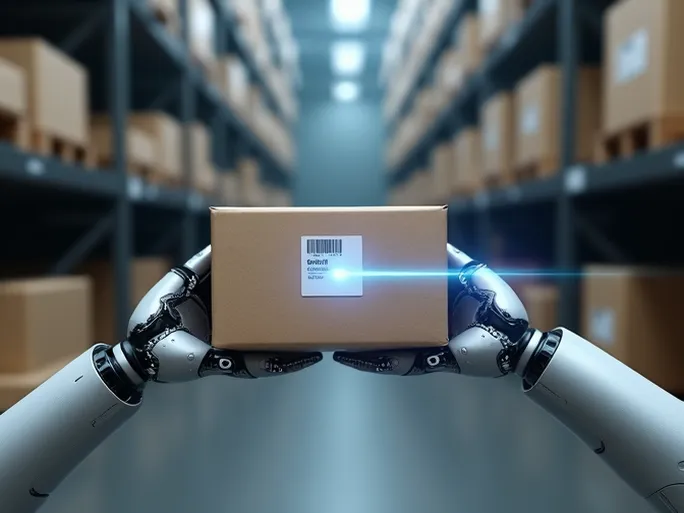

Imagine warehouse workers no longer needing to set down items to scan barcodes, instead using both hands simultaneously to efficiently sort and pack goods. This isn't science fiction—it's the reality being enabled by hands-free scanning technology. As e-commerce continues its rapid expansion, logistics efficiency has become a critical competitive differentiator. With rising labor costs creating operational pressures, hands-free scanning presents a promising solution for achieving productivity breakthroughs in warehouse operations.

Challenges and Opportunities in Modern Warehousing

The retail sector has maintained strong growth momentum in recent years. Industry analysts project the sector will continue expanding at a 10% compound annual growth rate through 2027. This growth creates tremendous pressure across supply chains—from warehouses and distribution centers to third-party logistics providers and last-mile delivery operations. To meet escalating consumer expectations for rapid order fulfillment, businesses must maximize productivity at every level. Optimizing workforce potential has become essential for operational success.

The Value Proposition of Hands-Free Scanning

In logistics operations, items processed per hour serves as a key efficiency metric. Traditional workflows often require workers to manually handle products while simultaneously scanning barcodes for traceability. Hands-free scanning technology enhances productivity by increasing throughput, eliminating unnecessary motions, and keeping workers' hands free. Key benefits include:

- Increased throughput: Wearable scanners like ring devices allow continuous scanning while maintaining full manual dexterity, reducing time wasted setting items down and significantly boosting processing speeds.

- Error reduction: Two-handed handling provides greater stability, minimizing drops and damage that frequently occur during one-handed scanning operations.

- Improved ergonomics: Conventional scanning often requires repetitive bending, reaching, or twisting that contributes to fatigue and workplace injuries. Hands-free solutions promote better posture and reduce musculoskeletal strain.

- Enhanced workforce satisfaction: More efficient and safer working conditions improve employee morale and retention rates.

Implementation Across Warehouse Operations

Hands-free scanning technology finds application throughout logistics workflows:

- Order picking: Ring scanners enable pickers to instantly scan shelf items without interrupting product handling, accelerating fulfillment speeds.

- Pallet building: Wearable devices verify load accuracy during pallet assembly, preventing errors that cause shipping delays.

- Sortation systems: Rapid package scanning on conveyor lines ensures proper destination routing with greater accuracy.

- Order consolidation: Hands-free verification during packing prevents shipping errors and improves order accuracy.

- Receiving/shipping: Accelerated scanning at dock doors improves inbound and outbound processing efficiency.

Deployment Considerations

While offering significant advantages, successful hands-free scanning implementation requires attention to several factors:

- Device selection: Matching scanner types (ring, wearable, etc.) to specific operational requirements and worker preferences.

- System integration: Seamless connectivity with warehouse management (WMS) and enterprise resource planning (ERP) platforms.

- Workforce training: Comprehensive education on proper device use and operational benefits.

- Maintenance protocols: Regular equipment servicing to ensure reliability and longevity.

The Future of Scanning Technology

Continued innovation points toward increasingly intelligent and integrated solutions. Next-generation devices may incorporate artificial intelligence for automatic product recognition with voice guidance, or augmented reality to overlay digital information onto physical workspaces. As competition intensifies across logistics sectors, hands-free scanning offers enterprises a powerful tool for boosting productivity, controlling costs, and improving workforce conditions—positioning the technology for expanded adoption in modern warehousing operations.