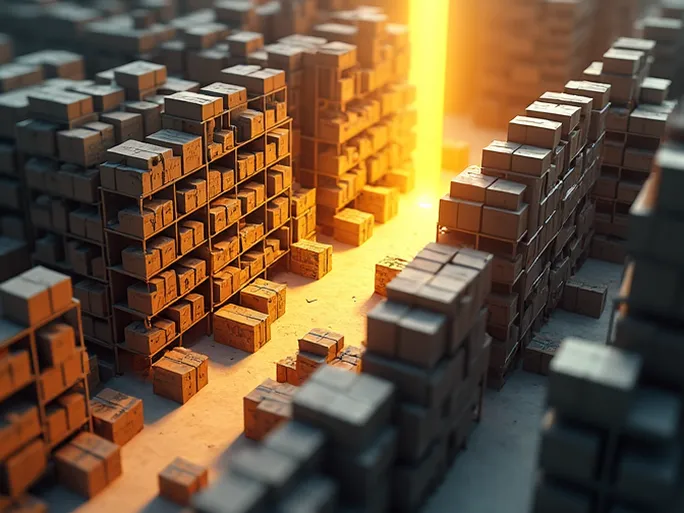

As the peak shopping season approaches, Amazon sellers are grappling with sudden reductions in storage capacity, with some even experiencing secondary cuts. The storage limits loom like a sword of Damocles, forcing sellers to reluctantly abandon inventory or transfer goods to third-party warehouses to avoid exorbitant overage fees. With shipping restrictions tightening, the critical question emerges: how can sellers secure sufficient stock to capitalize on seasonal demand?

Increasingly, sellers are turning to Amazon's Satellite Warehousing (STAR) and Amazon Warehousing & Distribution (AWD) programs as strategic solutions. These services function as covert tools, enabling merchants to bypass storage constraints and achieve their seasonal sales targets. By leveraging satellite warehouses, sellers can alleviate storage pressures and optimize inventory management, gaining a competitive edge in the crowded marketplace.

The capacity restrictions arrive during a pivotal period, when sellers typically ramp up inventory to meet anticipated holiday demand. Industry observers note that sellers adopting flexible fulfillment strategies—particularly those combining STAR with Amazon's fulfillment network—appear better positioned to navigate the constraints. The situation underscores the growing importance of diversified logistics planning in e-commerce operations.