Imagine this scenario: Your product has just rolled off the production line, and consumers are already eager to receive it. Yet traditional supply chain models operate like an endless relay race—plagued by cumbersome processes, information delays, extended delivery cycles, and excessive inventory buildup. These inefficiencies ultimately erode customer satisfaction and corporate profitability. The solution to this impasse may lie at "the edge."

Today's business environment demands faster, more cost-effective fulfillment and optimized inventory utilization. However, many brands and retailers lack the appropriate network infrastructure, analytical capabilities, and digital operational tools to ensure products are positioned correctly during the initial stages of their inventory lifecycle. This systemic lag not only increases operational costs but also constrains organizational agility in responding to market fluctuations.

I. The Limitations of Conventional Logistics Models

The traditional centralized logistics paradigm, reliant on massive warehouses and long-haul transportation, presents multiple disadvantages:

- Slow response times: Protracted order processing and delivery cycles struggle to meet consumers' growing expectations for immediacy.

- Excessive costs: Long-distance transportation, storage expenses, and inventory overstock drive unsustainable operational expenditures.

- Inflexibility: Systems remain vulnerable to demand volatility and disruptions, frequently resulting in stockouts or surplus inventory.

- Environmental impact: Extended transportation routes generate substantial carbon emissions, exacerbating ecological concerns.

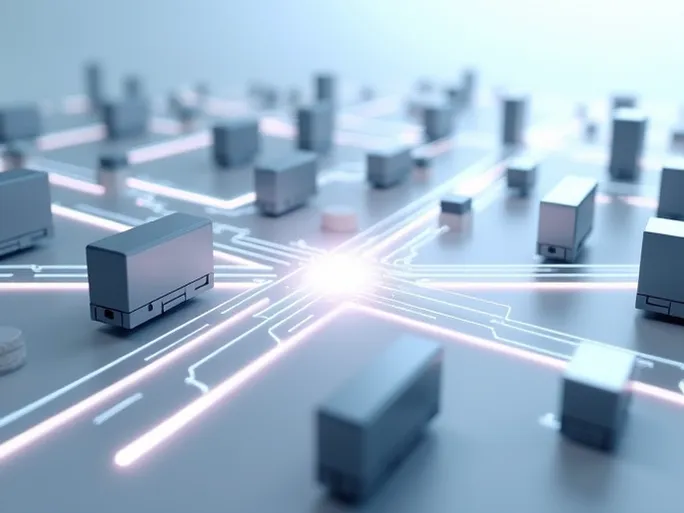

II. The Emergence and Advantages of Edge Logistics

"Edge logistics" represents a decentralized approach that positions storage and distribution assets closer to both consumers and suppliers. By establishing networks of smaller, more agile logistics nodes, organizations achieve accelerated delivery timelines and superior inventory optimization. Key benefits include:

- Reduced delivery windows: Forward-deploying inventory to proximity locations enables faster fulfillment and enhanced customer experiences.

- Lower operational costs: Minimizing long-haul transportation and warehousing needs while optimizing stock levels decreases overall expenditures.

- Increased adaptability: Enhanced capacity to respond to market shifts and unexpected disruptions strengthens supply chain resilience.

- Sustainability improvements: Reduced transportation distances yield lower carbon footprints, supporting environmental objectives.

III. Critical Components for Successful Edge Logistics Implementation

Effective deployment of edge logistics requires integration of several foundational elements:

- Distributed network architecture: Strategically located micro-fulfillment centers, localized distribution hubs, and pickup points create comprehensive coverage.

- Advanced analytics: Predictive modeling and big data applications optimize inventory positioning and routing efficiency.

- Digital transformation: IoT sensors, AI platforms, and blockchain technologies enable real-time tracking and information transparency.

- Collaborative partnerships: Strong alliances with third-party logistics providers, retailers, and suppliers foster synergistic ecosystems.

IV. Strategic Recommendations for Adoption

As edge logistics emerges as a defining trend in supply chain evolution, organizations seeking competitive advantage should consider these implementation steps:

- Conduct comprehensive supply chain assessments: Identify operational bottlenecks and establish clear edge logistics objectives.

- Develop phased implementation roadmaps: Address network design, technology integration, partner selection, and risk mitigation.

- Adopt incremental deployment: Begin with pilot programs before scaling operations, allowing for continuous optimization.

- Commit to ongoing innovation: Monitor technological advancements and market developments to refine edge logistics strategies.

This distributed approach to logistics represents a paradigm shift in how organizations manage inventory flow and customer fulfillment. By embracing edge principles, businesses can construct supply chains that are simultaneously more responsive, cost-efficient, and environmentally responsible—critical advantages in an era defined by rapid commerce evolution.