Imagine a highly automated warehouse where robots navigate seamlessly between shelves, efficiently fulfilling orders with precision. Yet, the foundation enabling this seamless operation often goes unnoticed—the racking system. Traditional racking solutions may no longer meet the growing demands of modern warehousing, requiring businesses to reevaluate their storage infrastructure to maximize space utilization and accelerate order fulfillment.

The Fundamentals of Racking Systems

Racking systems serve as the backbone of warehouse management, facilitating the storage and organization of goods. Far from being mere storage tools, they are critical for optimizing space and enhancing operational efficiency. Selecting the right racking system requires careful consideration of product characteristics, warehouse layout, and business objectives.

Limitations of Conventional Selective Racking

Selective racking, the most common type, provides individual pallet storage for easy access. However, its drawbacks become apparent in high-density storage scenarios: lower space efficiency due to excessive aisle space. For businesses storing large quantities of identical items, selective racking may not be the optimal choice.

Diverse Racking Solutions for Modern Needs

To address varying storage requirements, the market offers a range of specialized racking systems:

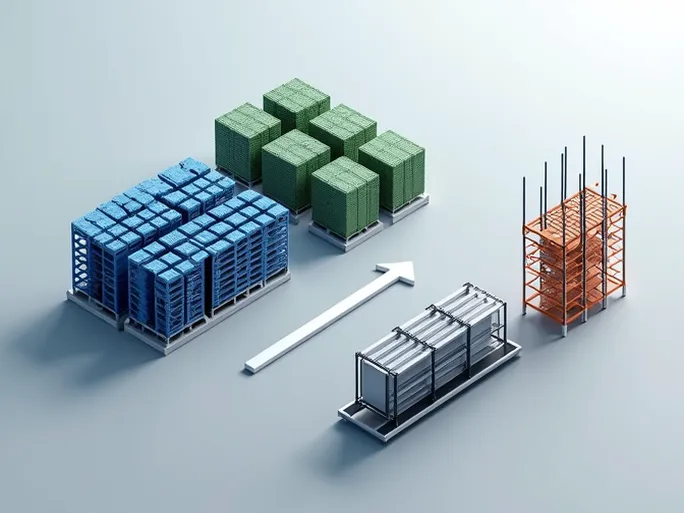

- Drive-in Racking: Ideal for bulk storage of uniform products, this system minimizes aisles to increase storage density. Forklifts can drive directly into the rack structure to load and unload pallets.

- Shuttle Racking: Combining drive-in racking with automation, this system uses remotely controlled shuttle carts to move pallets within the racks, significantly boosting efficiency.

- Mobile Racking: Motorized racks slide on tracks, creating access aisles only when needed. While offering exceptional space savings, this system requires higher upfront investment.

- Cantilever Racking: Designed for long or irregularly shaped items like pipes and lumber, its adjustable arms accommodate various lengths and weights.

- Mezzanine Racking: This vertical solution creates multi-level storage platforms, often integrated with staircases or lifts to maximize cubic space.

Key Considerations for Racking Selection

Choosing the appropriate racking system involves evaluating several critical factors:

- Product Characteristics: Dimensions, weight, shape, and special storage requirements (temperature, humidity) directly influence rack selection.

- Warehouse Configuration: Available floor space, ceiling height, column placement, and safety regulations constrain rack layout possibilities.

- Operational Requirements: Order frequency, picking methods, and automation levels dictate suitable rack configurations.

- Budget Constraints: Cost variations between systems necessitate balancing performance with financial considerations.

- Safety Compliance: Load capacity, structural stability, and fire resistance must meet stringent safety standards.

Safety and Regulatory Compliance

Racking safety remains paramount. Systems must be designed, installed, and maintained in accordance with relevant safety codes. Regular structural inspections, prompt replacement of damaged components, and comprehensive operator training are essential to prevent accidents.

Conclusion

Reevaluating racking systems enables businesses to select tailored solutions that optimize storage space, streamline operations, and ensure workplace safety. By leveraging diverse racking technologies, companies can effectively address evolving logistical challenges and strengthen their competitive position.