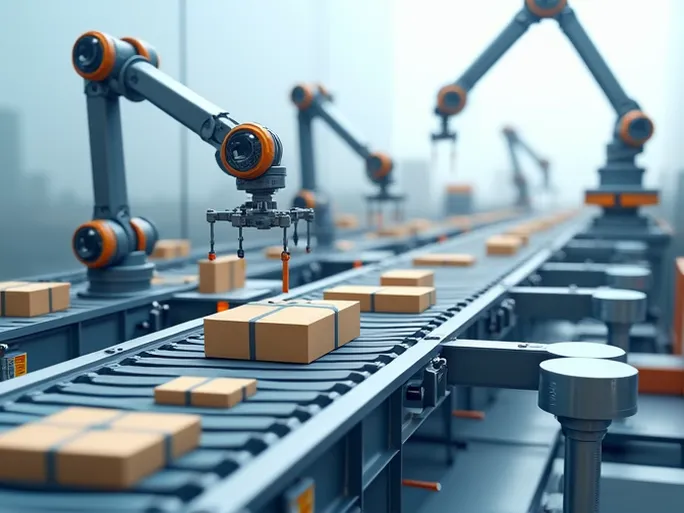

Imagine a future where bustling logistics centers no longer rely on crowds of manual laborers, but instead operate as precision systems driven by intelligent software and seamlessly coordinated automated equipment. This isn't science fiction—it's rapidly becoming reality. Under the dual pressures of fierce market competition and rising customer expectations, automation technology is penetrating every aspect of logistics centers at unprecedented speed, reshaping supply chain landscapes.

The Transformation of Logistics Centers in the Automation Wave

While automation in logistics centers isn't new, recent years have seen qualitative leaps in both development speed and implementation depth. Previous automation primarily handled simple repetitive tasks like conveyor belts and basic sorting systems. Today, advancements in artificial intelligence, machine learning, IoT, and robotics enable automation to manage complex, delicate operations including order picking, packaging, inventory management, and route optimization. This sophisticated automation boosts efficiency while reducing error rates and improving employee work environments.

Software-Driven Efficiency Optimization

In automated logistics centers, software plays a pivotal role. Beyond controlling automated equipment, it collects and analyzes vast data streams to optimize entire logistics workflows. Integrated software systems—including Warehouse Management Systems (WMS), Order Management Systems (OMS), and Transportation Management Systems (TMS)—enable seamless information flow and real-time decision making. By analyzing historical data, these systems can predict demand, optimize inventory levels, and adjust transportation routes based on real-time traffic conditions, maximizing efficiency while minimizing costs.

The System Integrator Perspective

Leading material handling system integrators play crucial roles in advancing logistics center automation. Beyond providing automated equipment, they offer specialized consulting, design, and integration services to develop customized automation solutions. Industry experts emphasize that successful automation requires phased implementation tailored to specific operational needs, with particular attention to employee training and engagement to ensure smooth adaptation to new workflows.

Future Outlook: The Boundless Potential of Automation Technology

Looking ahead, automation will expand deeper into logistics center operations. Emerging innovations include:

- Autonomous Mobile Robots (AMRs): These self-navigating robots perform picking, transport, and inventory tasks with greater flexibility than traditional Automated Guided Vehicles (AGVs), adapting dynamically to changing warehouse environments.

- AI-Powered Picking Robots: Capable of identifying and handling diverse item shapes and sizes, these robots significantly improve picking accuracy and efficiency.

- Augmented Reality (AR) Technology: AR assists workers in locating items faster while providing real-time operational guidance, reducing errors and boosting productivity.

- Digital Twin Technology: Virtual logistics center models enable better operational understanding and optimization of processes and resource allocation.

As automation technology evolves, logistics centers will become increasingly intelligent, efficient, and adaptable. Tomorrow's distribution hubs will better meet customer demands while creating greater business value. However, this technological progress must balance with workforce considerations—ensuring employees receive necessary training and support to thrive in transformed work environments. Only through this equilibrium can we achieve true harmony between human workers and machines, building a more productive future together.