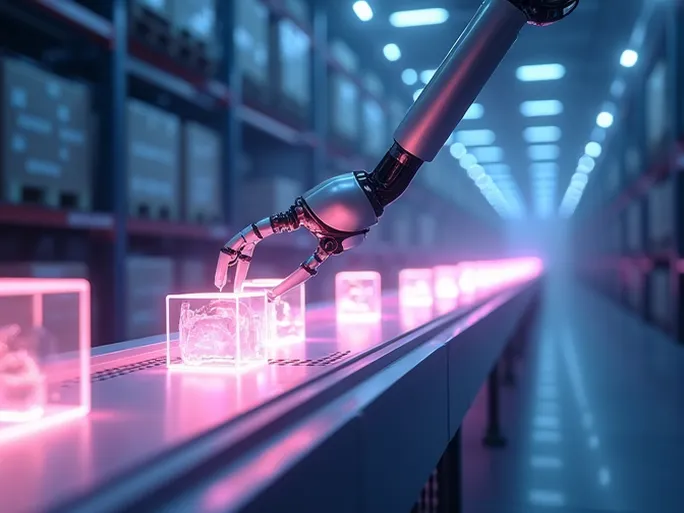

Imagine warehouses no longer filled with towering stacks of goods and exhausted workers rushing about, but instead populated by robots moving with precision and efficiency, with AI algorithms optimizing every process in real time. This is not some distant future scenario, but rather the profound transformation currently underway in California's logistics sector and across global supply chains. Faced with rising customer expectations and shrinking profit margins, California's material handling companies are actively embracing technological solutions to break through these challenges.

1. The Rise of Digital Freight Matching Platforms: Reshaping Brokerage

Traditional freight brokerage faces significant disruption from AI-powered digital freight matching platforms. These platforms automate workflows and improve capacity utilization, helping both shippers and carriers navigate ongoing freight market downturns. Industry leaders widely agree that technological adoption has become essential for business survival and growth.

Digital freight matching platforms are transforming brokerage through several key mechanisms:

- Automated workflows: AI algorithms automatically match shipping needs with available capacity, reducing manual intervention and improving efficiency.

- Enhanced capacity utilization: Real-time data analysis and intelligent optimization enable more effective use of existing transportation resources, reducing empty miles and lowering costs.

- Market resilience: During economic downturns, these platforms provide flexibility to adjust strategies, optimize resource allocation, and mitigate risks.

The December Edge report from C.H. Robinson confirms this trend, highlighting digital technology as a critical competitive differentiator for freight companies. Businesses must monitor market developments and proactively adopt new technologies to maintain their market position.

2. Logistics Technology Roundtable: AI and Automation in Supply Chains

From AI-powered Transportation Management Systems (TMS) to warehouse robotics and end-to-end automation, technology is fundamentally transforming logistics and supply chain operations. In a recent industry roundtable, four leading analysts shared insights on emerging logistics technology trends:

- AI in TMS: Artificial intelligence enables better demand forecasting, route optimization, and inventory management, improving transportation efficiency while reducing costs.

- Warehouse robotics adoption: Robots increasingly handle repetitive, physically demanding warehouse tasks, boosting operational efficiency while reducing labor costs.

- End-to-end automation: Integrated data across supply chain segments enables comprehensive automation, improving transparency, efficiency, and risk management.

Experts unanimously identified AI and automation as the primary drivers of future logistics innovation, with early adopters gaining significant competitive advantages.

3. WMS Advantages: How Leading Warehouses Outperform Competitors

Modern warehouses operate under constant pressure to deliver faster turnaround times, greater accuracy, real-time visibility, and seamless system integration - all while maintaining profitability. Industry leaders are addressing these challenges through advanced Warehouse Management Systems (WMS) that deliver:

- Operational efficiency: Optimized warehouse layouts, improved picking accuracy, and reduced error rates.

- Inventory control: Real-time tracking and optimized stocking strategies minimize overstock and shrinkage.

- Customer satisfaction: Faster order processing and improved delivery accuracy enhance client experiences.

WMS implementations provide specific competitive advantages through:

Precision Inventory Management

Real-time inventory visibility enables precise tracking of quantities, locations, and product conditions, supporting optimal stocking strategies and reducing capital tied up in inventory.

Optimized Layouts and Processes

Historical data analysis informs warehouse design and workflow improvements, such as optimized picking routes that minimize worker travel time.

Streamlined Order Processing

Automated order handling reduces manual steps, increasing processing speed and accuracy through direct e-commerce platform integration.

Advanced Analytics

Comprehensive operational data identifies performance bottlenecks and improvement opportunities, such as low-efficiency picking zones.

System Integration

Modern WMS solutions seamlessly connect with existing ERP and TMS platforms, enabling data sharing and coordinated processes across supply chains.

4. Navigating Technological Change: Strategies for California Logistics Firms

California's logistics companies must proactively address technological disruption to maintain industry leadership. Key recommendations include:

- Developing clear digital transformation roadmaps with defined objectives, priorities, and implementation timelines.

- Investing in technology infrastructure, software solutions, and skilled personnel while monitoring emerging innovations.

- Prioritizing workforce training programs to enhance technical competencies and adaptability.

- Fostering collaboration with technology providers, industry groups, and peer organizations to accelerate innovation.

California's material handling sector stands at a critical inflection point. Embracing technological transformation will determine which organizations thrive in an increasingly competitive and rapidly evolving logistics landscape.