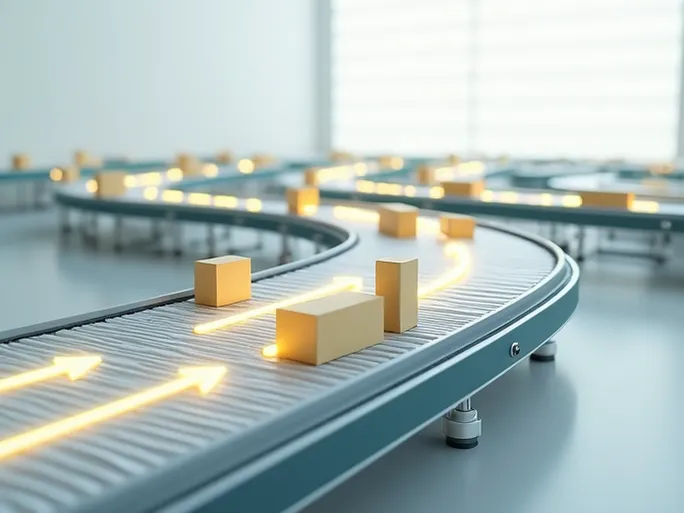

Imagine this: online orders flood in like a tidal wave, but delays in shipping due to inefficient warehouse operations lead to a surge in customer complaints. As consumer demand for instant delivery grows, warehouse management faces unprecedented challenges. While automation and robotics offer high-tech solutions, their steep costs and lengthy deployment timelines make them impractical for many businesses. Here are seven cost-effective, high-impact strategies to optimize warehouse operations and gain a competitive edge in e-commerce.

1. Inventory Layout Optimization

Traditional warehouse layouts often organize products by category or supplier, but e-commerce warehouses should prioritize order frequency and picking efficiency. Place high-demand items in easily accessible zones to minimize travel time. Implement the ABC classification method to rank products by priority, ensuring top-selling "A" items are always positioned optimally. Regularly analyze order data to dynamically adjust layouts in response to shifting sales trends.

2. Picking Strategy Enhancements

Order picking is one of the most time-consuming tasks in warehouse operations. Adopting strategies like wave picking, batch picking, or zone picking can dramatically improve efficiency. Wave picking groups orders by time windows or priority for consolidated processing, reducing redundant movement. Batch picking combines multiple orders to retrieve identical items in a single trip. Zone picking divides the warehouse into sections, assigning each picker to a specific area to increase specialization and speed.

3. Process Standardization and Training

Clear, standardized workflows paired with systematic employee training form the foundation of warehouse efficiency. Develop detailed operation manuals specifying responsibilities and procedures for each role. Conduct regular skill-building sessions to enhance staff proficiency. Standardization reduces human error and accelerates task completion.

4. Packaging Process Optimization

Packaging is a critical phase in e-commerce order fulfillment. Selecting appropriate materials and streamlining the packing process can lower shipping costs and minimize product damage. Automated packaging tools—such as box sealers or label applicators—boost output speed. Sustainable packaging solutions also reduce waste and improve brand perception.

5. Effective Inventory Management

Precise inventory control prevents both stockouts and overstocking. Deploy advanced inventory management systems to track stock levels in real time, forecast demand, and refine replenishment strategies. Routine audits ensure alignment between records and physical inventory. Efficient inventory practices cut holding costs and improve cash flow.

6. Improved Lighting and Ventilation

A well-maintained workspace boosts employee productivity and morale. Ensure adequate lighting, proper airflow, and comfortable temperatures. Energy-efficient lighting reduces operational expenses. Regular facility maintenance prevents disruptions.

7. Data-Driven Continuous Improvement

Warehouse operations require ongoing refinement. Collect and analyze metrics like order processing times, picking rates, and inventory turnover to identify bottlenecks and implement corrective actions. Periodically assess the impact of adjustments to iteratively enhance efficiency and profitability.