Imagine your warehouse during peak sales season—mountains of packages piling up, manual sorting unable to keep pace, delayed orders stacking up, and customer complaints flooding in as logistics costs devour your profits. This nightmare scenario keeps many e-commerce operators awake at night.

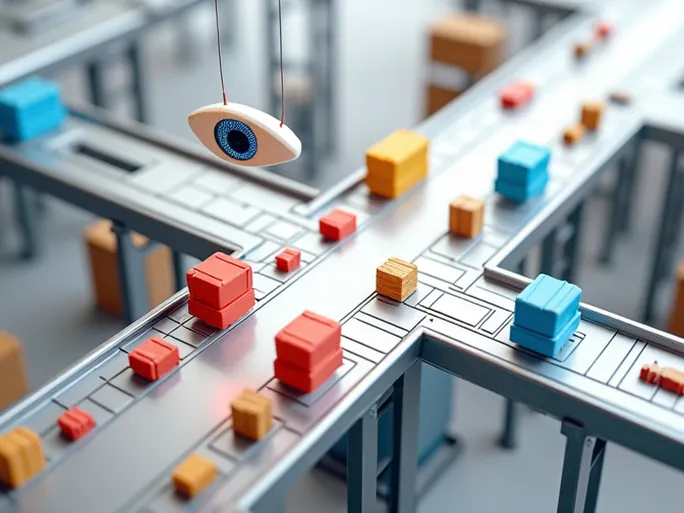

The solution? Intelligent vision sorting systems—the secret weapon that combines eagle-eyed precision with automated efficiency to supercharge your logistics operations.

Why E-Commerce Needs Smart Vision Sorting

In online retail, speed equals survival. Customers increasingly expect near-instant fulfillment after clicking "buy now." Lagging logistics don't just damage customer satisfaction—they directly impact repurchase rates and can cede market share to competitors.

Traditional manual sorting methods struggle with three critical limitations: inefficiency, error-proneness, and rising labor costs. During sales surges, human workers simply can't process the order tsunami, leading to warehouse gridlock and shipping delays.

Vision-based sorting systems solve these challenges through advanced image recognition that automatically reads barcodes, QR codes, text, and other package identifiers, then routes parcels to correct destinations using predefined rules.

Core Advantages of Vision Sorting Technology

- Dramatic efficiency gains: Processing speeds can exceed manual sorting by 10-100x, drastically reducing order cycle times.

- Near-perfect accuracy: Machine recognition achieves significantly higher precision than human workers, minimizing misroutes and associated losses.

- Labor cost reduction: Automated systems can replace large sorting teams while improving throughput.

- Enhanced customer experience: Faster, more reliable fulfillment builds loyalty and positive brand perception.

- Actionable intelligence: Real-time package tracking and data analytics enable continuous logistics optimization.

The Technology Behind the Vision

These systems combine sophisticated "eyes" and "brains":

Vision sensors capture high-resolution images of packages at high speeds, detecting barcodes, text, dimensions, colors and other identifiers with industrial-grade reliability.

Image processing algorithms analyze visual data with advanced pattern recognition, adapting to diverse packaging types and overcoming challenges like damaged labels or poor lighting.

Precision control systems translate recognition results into mechanical actions, coordinating conveyors, sorters and other automated equipment with millimeter accuracy at industrial speeds.

Selecting the Right System

Key evaluation criteria include:

- Throughput requirements: Match system capacity to your peak volumes and product mix.

- Integration capabilities: Ensure compatibility with existing warehouse management and transportation systems.

- Vendor expertise: Prioritize providers with proven implementation experience and robust support services.

- Total cost analysis: Consider both capital expenditure and long-term operational savings.

For e-commerce operations struggling with seasonal surges or seeking competitive advantage through logistics excellence, intelligent vision sorting represents a transformative investment. By automating the most labor-intensive warehouse process, businesses can achieve new levels of speed, accuracy and cost efficiency—turning logistics from a cost center into a strategic asset.