Critical Reminder: Is your production line prepared for the impending Lunar New Year? If not, you may be facing a potential supply chain crisis. While the U.S. has just concluded its holiday season, China and multiple Asian countries are preparing for their most important annual celebration—the Spring Festival and Lunar New Year. This massive celebration will bring regional operations to a near standstill for at least one week, making proactive procurement planning essential for organizations heavily reliant on these supply chains.

The Domino Effect of Lunar New Year Shutdowns

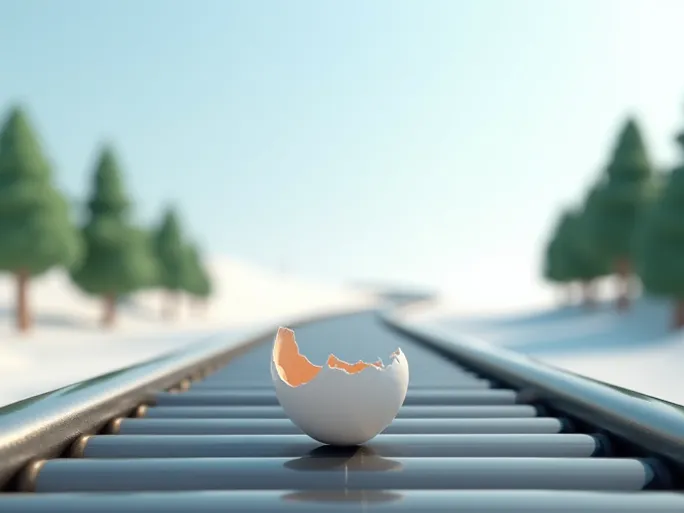

Imagine this scenario: Your production lines are operating at peak efficiency, orders are pouring in, and profits are soaring. Suddenly, a critical component shortage forces production to halt, order fulfillment becomes uncertain, customer complaints escalate, and profits plummet. The culprit? Likely your failure to account for the Lunar New Year shutdown.

This year, mainland China's official holiday period runs from January 24-30. Hong Kong observes a slightly shorter break from January 25-28. Countries including Indonesia, South Korea, Malaysia, Singapore, Taiwan, and Vietnam will experience varying degrees of operational slowdowns during this period. This isn't simply about factory workers taking vacations—it represents a complete disruption of the entire supply chain ecosystem.

Three Critical Impacts:

- Production Delays: Complete manufacturing stoppages during holidays create ripple effects. Even post-holiday, production rarely resumes immediately at full capacity due to worker return timelines, equipment recalibration, and production schedule reorganization.

- Transportation Bottlenecks: Logistics networks face extreme pressure both before and after the holidays. Pre-holiday shipment surges cause port congestion and transportation shortages, while post-holiday recovery efforts exacerbate delays with cargo backlogs and extended transit times.

- Capacity Crunch: Emergency restocking demands create intense competition for limited shipping capacity until normal operations resume, often requiring premium freight rates to secure space.

Expert Recommendations for Mitigation

Guido Gries, Managing Director of Dachser Americas, emphasizes: "China essentially shuts down during this period. Procurement managers must account for both the shutdown and the 30-day ocean transit time from Asia to the U.S. Capacity constraints and rate increases make transportation management critical."

Gries notes that Chinese manufacturers typically accelerate pre-holiday production: "Businesses should increase November imports to maintain adequate inventory through March. Creating buffer stock before year-end provides essential flexibility."

"The only way to eliminate supply chain bottlenecks is to procure early—getting products on vessels or planes before production slows or stops," states Joe Walden, Assistant Area Director of Analytics, Information, and Operations Management at the University of Kansas Business School.

Actionable Strategies:

- Conduct comprehensive inventory assessments to identify vulnerable components

- Implement "backward scheduling" from delivery dates to determine optimal procurement timelines

- Establish contingency plans for critical materials, including alternative suppliers

- Monitor real-time logistics conditions and adjust transportation modes as needed

Building Supply Chain Resilience

Walden advocates applying military-style contingency planning to commercial supply chains: "We developed response plans for every potential disruption scenario—most were never implemented, but their existence prevented crises. The same proactive approach applies to business procurement."

Key elements of resilient supply chains include:

- Supplier diversification to mitigate single-source vulnerabilities

- Strategic inventory buffers tailored to demand forecasts and lead times

- Flexible transportation networks with multimodal options

- Enhanced information sharing across supply chain partners

- Comprehensive risk assessment and mitigation protocols

Lessons from Industry Leaders

Several multinational corporations have successfully navigated Lunar New Year challenges through:

- Advanced Planning: Early supplier coordination and inventory positioning

- Transportation Flexibility: Multi-modal shipping strategies

- Supplier Diversification: Reducing dependence on single-region sourcing

- Risk Management: Systematic identification and mitigation of vulnerabilities

With proper preparation, businesses can transform this annual disruption from a crisis into a manageable operational event. The key lies in early action, comprehensive planning, and building adaptable supply chain structures capable of weathering predictable seasonal fluctuations.