In today's competitive business landscape, fast, efficient, and accurate logistics operations are crucial for corporate success. With the rapid growth of e-commerce and increasing consumer expectations for faster deliveries, companies face unprecedented pressure to optimize their warehouse operations.

The traditional "person-to-goods" picking method, where workers navigate warehouse aisles to locate items, is becoming increasingly inadequate for modern logistics needs. This outdated model suffers from inefficiency, high error rates, and rising labor costs. To address these challenges, a disruptive technology is transforming warehouse operations: Goods-to-Person (GTP) picking systems.

The Limitations of Traditional Picking Methods

Before examining GTP solutions, it's important to understand the constraints of conventional picking approaches:

- Inefficiency: Workers spend significant time walking through warehouses, with travel time accounting for a major portion of picking cycles.

- Error-prone: The physical search process leads to mistakes like incorrect items, missed picks, or quantity errors, increasing returns and customer complaints.

- High labor costs: Low productivity requires more staff to meet order volumes, escalating wage and training expenses.

- Poor space utilization: Extensive aisle space reduces storage density and increases real estate costs.

- Worker dissatisfaction: Repetitive walking and searching leads to fatigue and disengagement among staff.

The GTP Advantage

Goods-to-Person systems automate product delivery to stationary pickers, offering transformative benefits:

- Enhanced productivity: Eliminating travel time can double or triple picking rates compared to manual methods.

- Improved accuracy: Automated delivery and digital instructions reduce human errors to near-zero levels.

- Cost reduction: Fewer workers and better space utilization lower operational expenses.

- Employee satisfaction: Ergonomically designed workstations reduce physical strain and fatigue.

- Faster fulfillment: Accelerated processing enables same-day or next-day delivery capabilities.

GTP System Variants

Multiple GTP technologies serve different operational needs:

- AS/RS: Automated storage/retrieval systems for high-density, fast-moving inventory

- Shuttle systems: Medium-density solutions with horizontal transport vehicles

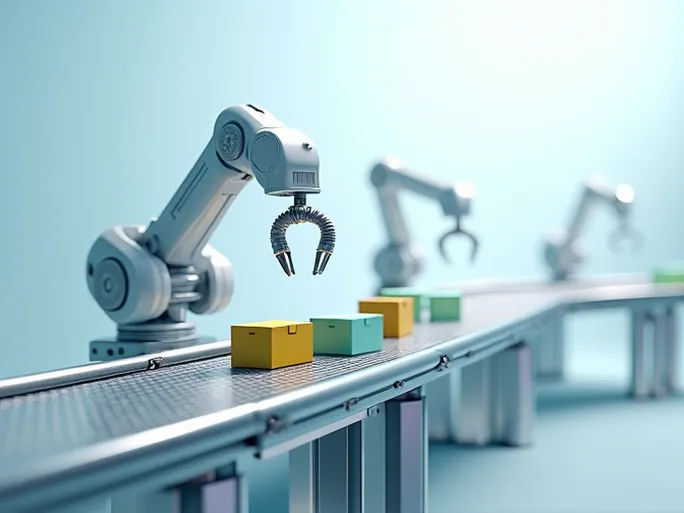

- Robotic picking: Autonomous mobile robots for flexible, scalable operations

- Carousels: Rotating systems ideal for small, high-value items

- Conveyor systems: Cost-effective solutions for large, bulky products

Implementation Challenges

While GTP offers compelling benefits, adoption presents several hurdles:

- Capital intensity: Significant upfront investment in automation hardware and software

- Technical complexity: Integration requires specialized engineering expertise

- Extended timelines: Implementation cycles often span 6-12 months

- Operational disruption: Installation may temporarily impact warehouse throughput

- Workforce training: Staff require new skills to operate advanced systems

The Role of Logistics Partners

Third-party logistics providers play a critical role in GTP adoption, offering:

- Needs assessment and solution design

- Technology selection and vendor management

- System integration and implementation

- Staff training and change management

- Ongoing optimization and maintenance

Industry Leadership in Automation

Leading logistics providers have emerged as automation specialists, with capabilities including:

- Multi-vendor technology ecosystems

- Proven implementation methodologies

- Performance benchmarking

- Continuous improvement programs

- Early adoption of emerging technologies

Case Study: E-commerce Transformation

A rapidly growing online retailer implemented a shuttle-based GTP system through a logistics partnership, achieving:

- 50% increase in picking productivity

- 99.9% order accuracy

- 30% reduction in labor costs

- 20% improvement in storage density

The Path Forward

As supply chains continue digitizing, GTP systems represent a strategic investment for companies seeking to:

- Scale operations efficiently

- Meet evolving customer expectations

- Control labor costs

- Future-proof warehouse infrastructure