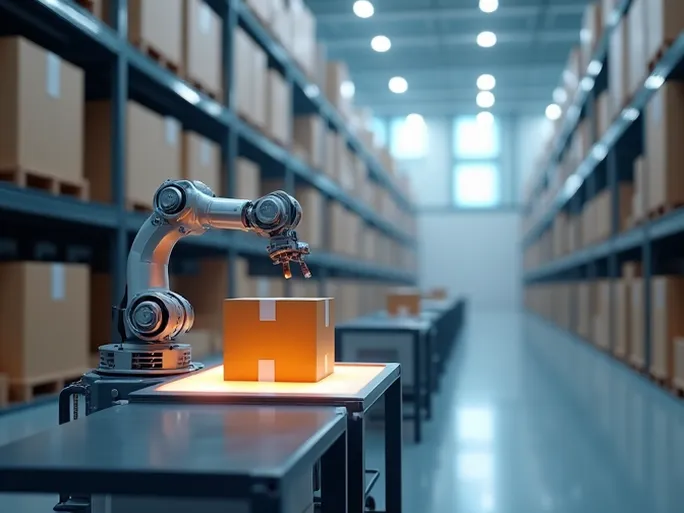

Imagine a warehouse where workers no longer spend their days navigating endless aisles in search of products. Instead, goods come directly to them through an automated system that maximizes efficiency and minimizes fatigue. This is the promise of Goods-to-Person (GTP) technology, which represents not just a technological upgrade but a fundamental shift in warehouse operations philosophy.

The Limitations of Traditional Person-to-Goods Systems

Before examining GTP solutions, it's important to understand the drawbacks of conventional person-to-goods systems that have dominated warehouses for decades:

- Inefficiency: Workers spend significant time walking through warehouses, particularly in large facilities where travel distances between shelves can be substantial.

- High costs: The time spent walking increases labor expenses, while lower productivity often requires hiring additional staff to meet order volumes.

- Error rates: Manual picking processes lead to mistakes, especially when handling similar-looking items, resulting in returns and reshipments.

- Worker fatigue: Constant walking and repetitive motions contribute to physical exhaustion, affecting both productivity and employee retention.

- Space utilization: Wide aisles required for worker access reduce storage density in increasingly expensive real estate markets.

The GTP Advantage: A New Paradigm for Warehousing

GTP systems reverse the traditional workflow by delivering items directly to stationary picking stations. This approach offers multiple benefits:

- Increased efficiency: Eliminating travel time can improve picking rates by 2-4 times compared to conventional methods.

- Faster order cycles: Reduced picking times translate to quicker order fulfillment and improved customer satisfaction.

- Enhanced accuracy: Stationary picking allows greater focus, while integrated scanning systems provide verification.

- Improved ergonomics: Reduced physical strain leads to better working conditions and higher productivity.

- Lower labor costs: Higher throughput enables operations to handle more orders with fewer personnel.

- Optimized space: High-density storage configurations maximize warehouse capacity.

Implementing GTP: Key Considerations

Transitioning to GTP requires careful planning and execution. Organizations must evaluate several factors:

Technology Options

Various GTP solutions exist, each suited to different operational needs:

- Shuttle-based systems: Automated vehicles retrieve items from high-density storage for high-volume operations.

- Robotic solutions: Flexible autonomous robots adapt to changing inventory and warehouse layouts.

- Vertical lift modules: Space-saving vertical systems ideal for facilities with height advantages.

- Carousel systems: Rotating units that efficiently manage diverse SKUs in limited spaces.

Implementation Challenges

While promising, GTP adoption presents several hurdles:

- Substantial upfront investment in hardware, software, and integration

- Complex design requirements specific to each operation

- Potential disruption during installation and transition periods

- Integration with existing warehouse management and enterprise systems

- Workforce training for new processes and technologies

The Role of Third-Party Logistics Providers

Third-party logistics (3PL) partners have emerged as valuable allies in GTP implementation, offering:

- Specialized expertise in evaluating and selecting appropriate technologies

- Implementation experience to avoid common pitfalls

- Customized solutions tailored to specific operational needs

- Flexible financial models to manage capital requirements

Forward-thinking 3PLs are establishing partnerships with automation vendors and developing operational expertise to optimize GTP deployments. These providers help organizations navigate the transition while maintaining service levels during implementation.

Case Study: Successful GTP Implementation

One e-commerce retailer facing rapid growth partnered with an experienced 3PL to implement a shuttle-based GTP system. The results included:

- 300% improvement in picking efficiency

- 50% reduction in order cycle times

- 30% decrease in labor costs

- 99.99% order accuracy rate

The Future of Warehouse Automation

GTP technology represents a critical component in broader supply chain digital transformation strategies. When combined with other innovations like artificial intelligence and IoT systems, these solutions create smarter, more responsive logistics networks.

Successful adoption requires careful technology selection, thorough planning, and often partnership with experienced logistics providers. Organizations that implement GTP strategically can achieve significant competitive advantages in today's demanding fulfillment environment.