Imagine traditional manufacturing struggling with supply chain disruptions when a "savior" emerges—capable of producing needed parts on demand. Could this fundamentally transform the industry? Brooklyn-based startup Voodoo Manufacturing is turning this vision into reality through its robot-powered 3D printing technology, poised to revolutionize small-batch parts production.

The company recently announced securing $5 million in new funding from investors including General Catalyst and Y Combinator Continuity Fund, bringing its total investment to $6.4 million. These funds will expand its robotic 3D printing factory and accelerate technological innovation.

Automated Production at Scale

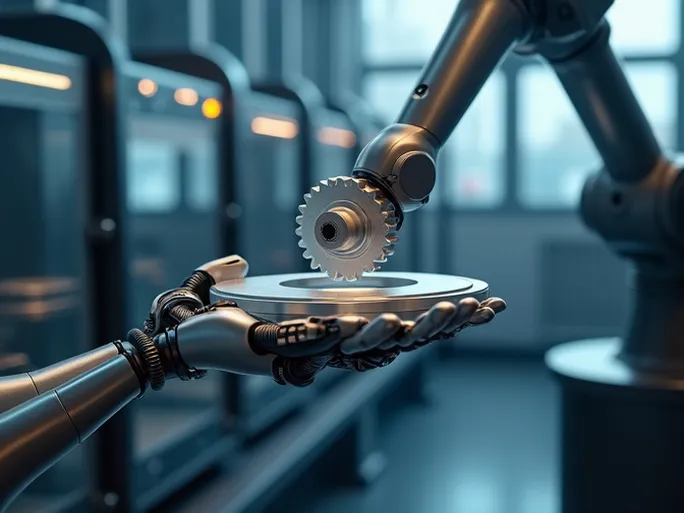

Voodoo Manufacturing's competitive edge lies in its highly automated production process. The facility operates 160 3D printers managed by custom-built robots that handle repetitive tasks like print bed swapping and machine restarts. These robotic systems—comprising sensors, arms, grippers, and other components—operate continuously, significantly boosting production efficiency and flexibility.

The company targets the small-batch, customized parts market where traditional manufacturing often struggles with high costs and long lead times. Voodoo's approach delivers quality components faster and more affordably, meeting specialized customer needs.

Industry Implications

Supply chain experts suggest Voodoo's emergence signals 3D printing's growing role in small-batch manufacturing. The company represents both an early adopter of disruptive production methods and a pioneer in robotic task management. As technology matures and costs decline, 3D printing may increasingly replace conventional methods for specialized applications.

A notable case involved Volkswagen facing production delays last year due to supplier issues. Access to 3D printing could have enabled rapid production of required cast iron parts, avoiding supply chain losses—demonstrating Voodoo's potential to address such challenges.

Workforce Considerations

While Voodoo's current small scale limits employment impact, broader adoption of automated 3D printing raises concerns about traditional manufacturing jobs. One investor suggests manufacturing's future lies in human-robot collaboration, requiring workers to develop programming and maintenance skills. This transition underscores the need for expanded training programs to facilitate workforce adaptation.

CEO Interview: The Future of Manufacturing

What is Voodoo Manufacturing's core advantage?

"Our strength combines 3D printing with robotic automation to create an exceptionally flexible, efficient production platform. This allows faster, more affordable production of high-quality custom parts."

How do you see 3D printing's role in manufacturing evolving?

"3D printing will grow increasingly vital. As technology advances and costs decrease, it will progressively replace traditional methods, particularly for small-batch customized components where it offers clear advantages."

Does robotic automation threaten employment?

"While some traditional jobs may transition, new opportunities will emerge in programming and system maintenance. We must invest in training to help workers adapt."

What's Voodoo's strategic direction?

"We'll expand our robotic 3D printing operations while accelerating innovation—optimizing processes, improving efficiency, reducing costs, and exploring new applications to deliver comprehensive solutions."

Technical Capabilities

Voodoo's technological strengths include:

Automated Production: 160 printers managed by custom robots handling repetitive tasks, maximizing efficiency.

Advanced Printing: High-precision components using cutting-edge materials and evolving techniques.

Software Platform: Proprietary system automating order management, process optimization, and equipment monitoring.

Industry Applications

The company's technology serves multiple sectors:

Aerospace: Custom aircraft components reducing weight and improving fuel efficiency.

Automotive: Prototypes and specialized parts accelerating development cycles.

Medical: Patient-specific implants and surgical instruments enhancing precision.

Consumer Goods: Customized products and packaging meeting individual preferences.

Voodoo Manufacturing exemplifies manufacturing's transformation through 3D printing and automation. By merging these technologies, the company achieves unprecedented production agility and efficiency. As applications expand, such innovations may increasingly reshape industrial processes and economic structures.