Have you ever felt overwhelmed by overflowing warehouse inventory? Struggled with unpredictable demand fluctuations? In today's rapidly evolving market, warehouse management has evolved beyond simple storage solutions to become the critical nexus of supply chain efficiency. Traditional approaches, relying on experience-based decision-making and manual operations, often face challenges like inventory pileups, sluggish response times, and soaring operational costs. Now, the rise of artificial intelligence (AI) is driving a profound transformation in warehouse management, ushering in a new era of intelligent warehousing.

I. The Challenges of Traditional Warehousing: Efficiency Bottlenecks and Cost Pressures

Warehouse management has long confronted numerous obstacles. First, inaccurate demand forecasting leads to either excess inventory or shortages, directly impacting cash flow and customer satisfaction. To hedge against potential supply disruptions, companies often maintain excessive safety stock levels, which inflates storage costs and increases the risk of inventory obsolescence.

Second, manual operations prove inefficient, with picking and transporting goods consuming excessive time and labor while being prone to errors. The explosive growth of e-commerce has dramatically increased both order volumes and SKU counts, making traditional manual methods increasingly inadequate.

Furthermore, information asymmetry creates significant problems. Without real-time, comprehensive data, managers lack visibility into critical metrics like inventory status and operational efficiency, hampering their ability to make informed decisions.

II. AI Empowerment: Reinventing Warehouse Management Processes

The rapid advancement of AI technology offers innovative solutions to these traditional warehousing challenges. AI enhances warehouse management in several key areas:

- Smart Forecasting and Inventory Optimization: AI algorithms analyze historical sales data, market trends, seasonal patterns, and multiple data sources to generate more accurate demand predictions. By optimizing inventory strategies, companies can reduce safety stock levels, minimize excess inventory and waste, while improving capital utilization.

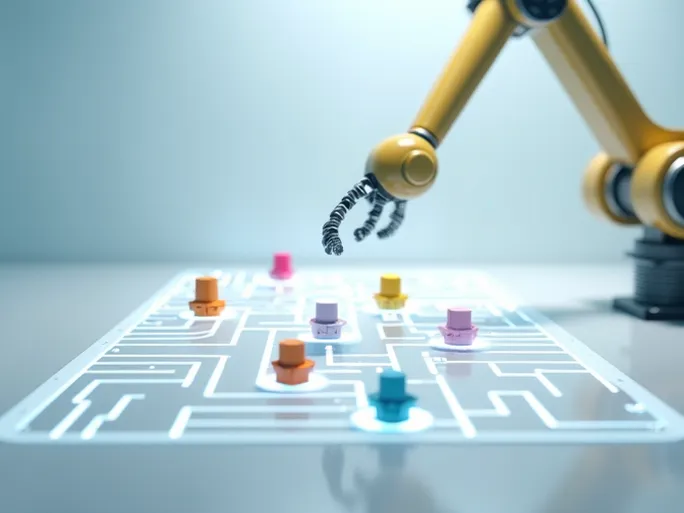

- Automated Operations for Efficiency Gains: Robotics, drones, and other automated equipment are becoming commonplace in modern warehouses. AI-powered systems can direct these devices to perform picking, transportation, and sorting tasks, significantly boosting operational efficiency while reducing labor costs.

- Intelligent Monitoring and Layout Optimization: Computer vision technology enables real-time monitoring of inventory storage and personnel activities, allowing for immediate anomaly detection. By analyzing spatial data, companies can optimize warehouse layouts to maximize space utilization and minimize unnecessary movement.

- Data-Driven Decision Making: AI systems perform deep analysis of operational data, generating visual reports that help managers identify inefficiencies and improvement opportunities. This data-centric approach enables continuous process optimization.

III. Case Studies: AI Applications in Warehouse Operations

Numerous global enterprises have implemented AI in warehouse management with measurable success. Amazon's robotic systems have automated warehouse operations, dramatically accelerating order processing while improving accuracy. JD Logistics has used AI algorithms to optimize storage layouts and delivery routes, enhancing efficiency while controlling costs. Alibaba's Cainiao Network employs AI for intelligent forecasting and inventory optimization, reducing excess stock and waste.

These examples demonstrate AI's vast potential in warehouse management. As the technology advances and becomes more cost-effective, its role in logistics operations will continue expanding.

IV. Future Outlook: The Boundless Potential of Smart Warehousing

Looking ahead, intelligent warehousing will evolve along several key trajectories:

- Increased Intelligence: AI will become more deeply integrated across all warehouse operations, enabling higher levels of automation and autonomous decision-making.

- Enhanced Flexibility: Warehouse systems will adapt more quickly to market changes, accommodating personalized and customized demands.

- Improved Collaboration: Warehouses will integrate more seamlessly with supply chain partners through data sharing and resource optimization.

- Greater Sustainability: Eco-friendly materials and energy-efficient technologies will become standard in warehouse design and operations.

AI-powered smart warehousing enables companies to overcome traditional limitations, improving efficiency, reducing costs, and optimizing resource allocation to gain competitive advantage. Embracing AI represents a critical step toward achieving supply chain excellence.