Imagine customers being able to track every stage of their order journey—from the moment of purchase to final delivery—with complete visibility. This goes beyond enhancing customer experience; it builds brand loyalty. Transparent supply chains are reshaping consumer expectations and emerging as a critical competitive advantage.

Transparent Supply Chains: The New Competitive Edge

As predicted by industry analyses, supply chains were expected to become fully customer-centric by 2020. While that timeline has passed, the core principle remains valid: customer expectations continue to drive supply chain transformation. In today's interconnected world, consumers demand more than simple "order shipped" notifications. They want to know a product's origin, whether ethical standards were maintained during production, and if sustainable practices were followed during transportation.

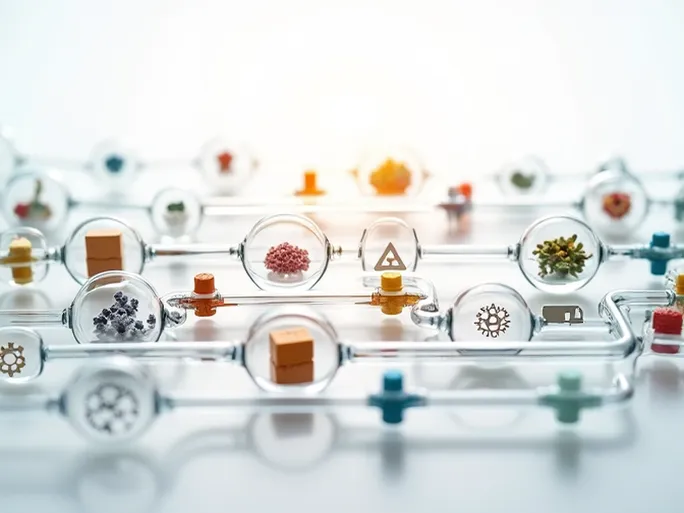

Businesses must develop end-to-end supply chain networks that achieve true transparency. This requires moving beyond traditional linear models to view supply chains as complex, interconnected systems where every node must be visible—allowing customers to observe and evaluate each step.

From Linear to Networked: A Paradigm Shift

Traditional supply chain models followed a straightforward sequence: raw material procurement → manufacturing → warehousing → final delivery. This approach created information lags, leaving customers passively waiting without process visibility. Digital transformation has rendered this model obsolete.

Modern supply chains function as intricate relationship networks where each node interacts with multiple others simultaneously. A single supplier might provide materials to numerous manufacturers, while manufacturers source from multiple suppliers, and logistics providers serve various producers concurrently. This complexity makes transparency both more challenging and more essential than ever.

Risk Management: The Core of Transparent Supply Chains

Supply chain transparency extends beyond tracking product locations—it involves communicating potential risks and mitigation strategies. Three key resilience factors define robust supply chains:

- Basic Resilience: Capacity to withstand disruptions like natural disasters, supplier bankruptcies, or transportation failures. Companies need robust warning systems and contingency plans.

- Strategic Resilience: Ability to adapt to market shifts, competitive pressures, or technological changes through continuous environmental scanning.

- Operational Resilience: Capability to manage routine fluctuations like seasonal demand variations or production adjustments through flexible planning systems.

Implementation Strategies for Transparent Supply Chains

Building transparent supply chains requires strategic planning and phased execution:

- Data Integration: Establish unified platforms combining IoT, blockchain, and cloud technologies for real-time data collection and analysis.

- Visualization Tools: Deploy customer-facing interfaces showing real-time order tracking, delivery estimates, and route mapping.

- Vendor Management: Collaborate with suppliers to establish transparency standards and conduct regular evaluations of production practices.

- Customer Engagement: Maintain open communication channels through multiple platforms to gather feedback and share updates.

- Technology Adoption: Leverage AI and machine learning for predictive analytics, inventory optimization, and bottleneck identification.

The Tangible Benefits of Transparency

Organizations implementing transparent supply chains gain multiple advantages:

- Enhanced customer trust and brand loyalty through verifiable product journeys

- Reduced operational costs by identifying inefficiencies and optimizing inventory

- Improved risk management through real-time monitoring and rapid response capabilities

- Stronger brand reputation by demonstrating corporate responsibility

Industry Examples: Transparency in Action

Forward-thinking companies across sectors demonstrate transparency's value. Apparel brands disclose factory conditions and manufacturing processes, while food producers share sourcing details and agricultural practices. These initiatives build consumer confidence and differentiate brands in competitive markets.

Conclusion: Transparency as a Business Imperative

In increasingly competitive markets, supply chain transparency has become fundamental for customer retention. Organizations must embrace end-to-end visibility, foster collaborative partnerships, and integrate transparency into corporate culture. As technologies like blockchain and AI advance, transparent supply chains will grow more sophisticated—offering companies that adopt them sustained competitive advantage.