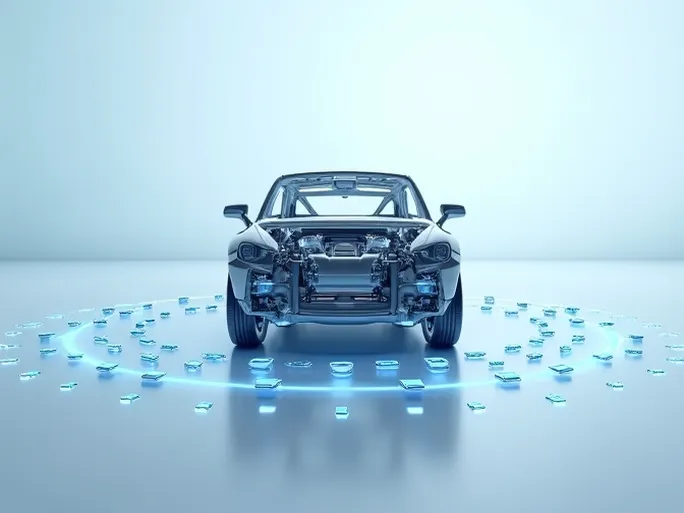

Imagine a massive automobile assembly plant operating like a high-speed precision machine. Thousands of components flow like blood through its veins while hundreds of vehicles await transformation at various workstations. This vibrant scene can quickly descend into chaos without an efficient tracking system.

Traditional tracking methods relying on manual records and barcode scanning prove inefficient and error-prone, like searching for a needle in a haystack. These outdated approaches consume time and resources, ultimately dragging down production lines and eroding profits.

RFID: The Manufacturing "Eagle Eye" That Provides Total Control

Honda's Greensburg, Indiana plant pioneered the implementation of RFID (Radio Frequency Identification) technology, effectively solving production tracking challenges and achieving remarkable efficiency gains. Each new vehicle receives its own "identity card" - a lightweight, durable passive RFID tag that stores critical information including model, configuration, and production batch.

As vehicles pass key checkpoints, strategically placed RFID readers automatically scan these tags and upload data to central control systems. This eliminates manual intervention and barcode scanning, completing the process instantly. Plant managers gain real-time visibility into each vehicle's location and status, enabling them to monitor progress, identify bottlenecks, and implement optimizations.

Passive RFID: The Cost-Effective Solution for Large-Scale Implementation

After careful consideration, Honda selected passive RFID technology for its Greensburg facility. Unlike active RFID tags that require batteries, passive tags operate using radio waves emitted by readers. This eliminates battery replacement needs and significantly reduces maintenance costs.

While passive RFID offers shorter read ranges compared to active systems, its lower cost and simplified maintenance make it ideal for large-scale vehicle tracking applications. The Greensburg plant, producing approximately 10,000 vehicles daily, benefits from this technology's ability to streamline location processes and eliminate inefficiencies associated with manual tracking.

Tangible Benefits: Reduced Costs, Enhanced Efficiency

Since implementing RFID, Honda reports significant cost reductions and productivity improvements at its Greensburg facility. Key benefits include:

Precise Location Tracking: RFID enables rapid vehicle identification, preventing production delays caused by misplaced units.

Real-Time Process Optimization: Continuous monitoring allows for immediate identification and resolution of bottlenecks.

Data-Driven Improvements: Collected data facilitates comprehensive production analysis and continuous process enhancement.

Future Applications: Logistics Optimization and Smart Factory Development

Honda plans to expand RFID applications beyond vehicle tracking to include logistics optimization. Tracking component transportation and storage will improve inventory control, reduce waste, and enhance supply chain transparency.

The technology's potential extends to tool and equipment tracking, production environment monitoring, and quality data collection for design improvements. Encapsulated in protective coatings, RFID tags perform reliably even in harsh industrial environments, while their non-line-of-sight capability enhances worker safety in complex operations.

RFID: A Key Driver of Digital Transformation in Manufacturing

The Honda Greensburg case demonstrates RFID's transformative potential in industrial settings. As a cost-effective automated identification solution, this technology serves as a critical component in manufacturing digital transformation.

Beyond automotive applications, RFID shows promise in aerospace (component tracking), electronics manufacturing (part tracking), medical devices (anti-counterfeiting), and apparel production (supply chain visibility). Regardless of industry or company size, RFID technology offers substantial value for operational improvement.

Successful RFID implementation requires careful consideration of technology selection, data security measures, system integration with existing platforms, and comprehensive employee training. When properly deployed, RFID systems create transparent supply chains that improve inventory management and risk mitigation while functioning reliably in demanding production environments.