A safety crisis stemming from defective airbags that claimed 16 lives has pushed Japanese supplier Takata to the brink of bankruptcy. The $1 billion settlement with the U.S. Department of Justice appears to be the final straw. Yet for Japanese automakers deeply tied to Takata, this crisis didn't come as a complete surprise. How are these manufacturers preparing for the potential impact of Takata's collapse while restructuring their supply chains?

The Inevitable Collapse and Potential Consequences

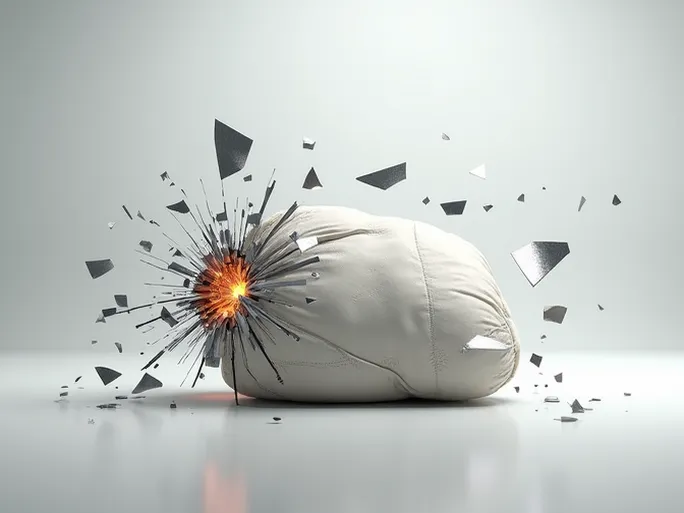

Takata's airbag defects triggered global recalls affecting tens of millions of vehicles. The propellant in these airbags could deteriorate when exposed to prolonged heat and humidity, causing explosive deployments that sprayed metal shrapnel at occupants. This catastrophe brought massive financial losses and reputational damage to Takata while prompting industry-wide reassessments.

While not yet officially declared, Takata's bankruptcy has become an industry expectation with several likely consequences:

- Supply chain disruptions: Bankruptcy proceedings may impair Takata's production and delivery capabilities, potentially causing manufacturing delays or stoppages.

- Increased recall costs: Automakers face massive expenses replacing Takata airbags, with bankruptcy potentially limiting compensation recovery.

- Brand reputation damage: Partner automakers may face consumer skepticism about vehicle safety.

Japanese Automakers' Risk Mitigation Strategies

Japanese manufacturers have proactively implemented several strategies to minimize disruption:

1. Establishing contingency funds: Companies including Honda and Nissan anticipated Takata's troubles, creating dedicated reserves to cover recall-related expenses and cushion financial impacts.

2. Diversifying suppliers: To reduce dependence on Takata, automakers are forging relationships with alternative suppliers like Sweden's Autoliv, ensuring more stable parts availability.

3. Advancing technological solutions: Some manufacturers are developing new airbag technologies featuring improved propellants and safer designs to prevent similar failures.

4. Strengthening quality controls: The crisis has prompted stricter supplier vetting processes and enhanced quality testing protocols across the industry.

Autoliv's Ascent and Shifting Market Dynamics

As Takata falters, Autoliv has emerged as a primary beneficiary. The Swedish supplier's reliable products and stable operations have attracted growing automaker interest, with projections to deliver 30 million airbags by 2018 according to industry reports.

Autoliv's rise has reshaped competitive dynamics while presenting new supply chain challenges. Automakers must reevaluate supplier networks and cultivate stable partnerships with new providers.

Lessons Learned: Risk Management and Supply Chain Resilience

The Takata crisis offers critical lessons for global manufacturing:

- Supplier diversification: Overreliance on single suppliers creates vulnerability. Multiple sources provide stability.

- Enhanced supplier oversight: Regular audits and monitoring ensure quality standards and production capabilities.

- Comprehensive contingency planning: Prepared response protocols minimize disruption when crises occur.

- Collaborative supplier relationships: Strong partnerships enable joint problem-solving and risk mitigation.

- Continuous innovation: Technological improvements enhance product safety and reliability.

Japanese Automakers' Supply Chain Transformation

The Takata crisis has accelerated Japanese manufacturers' supply chain restructuring efforts:

Building resilient networks: Companies are creating more flexible supply chains through diversified sourcing, optimized inventory management, and improved logistics.

Digital transformation: Automakers are implementing data analytics and AI solutions to increase supply chain transparency and efficiency.

Technology partnerships: Collaborations with emerging tech firms aim to develop safer, smarter automotive solutions.

Industry standards participation: Active engagement in standard-setting promotes sector-wide improvements.

The Takata crisis underscores that effective risk management remains fundamental to sustainable business operations. Japanese automakers' proactive measures—from financial preparations to supply chain diversification—demonstrate valuable approaches to navigating supplier crises while building foundations for future stability.