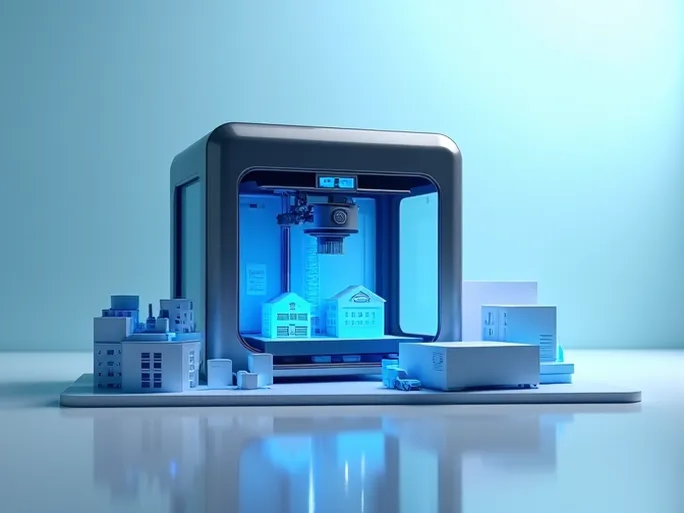

Imagine factories of the future no longer filled with warehouses of spare parts, but instead equipped with flexible 3D printers capable of producing customized components on demand. This vision is becoming reality faster than many anticipated, thanks to strategic partnerships like the one between SAP and Stratasys.

To empower clients, employees, and partners, these industry leaders have established a network of 3D collaborative innovation labs designed to accelerate the adoption of additive manufacturing (3D printing) technology. Announced last week, this partnership focuses on demonstrating the transformative potential of 3D printing in supply chain management through distributed manufacturing applications.

3D Collaborative Innovation Labs: Accelerating Adoption

The innovation labs provide participants with hands-on experience demonstrating how 3D printing can revolutionize supply chain efficiency through several key advantages:

- Faster design cycles: Rapid prototyping capabilities allow companies to quickly translate concepts into physical models, dramatically shortening product development timelines.

- Digital file transmission: Replacing physical shipments with digital files eliminates geographical barriers, enabling global collaborative manufacturing.

- Reduced inventory: On-demand production minimizes warehouse storage needs for rarely used components, lowering operational costs.

3D Printing: The New Engine Reshaping Supply Chains

Additive manufacturing is driving profound changes in supply chain management as more companies recognize its potential. The SAP-Stratasys collaboration exemplifies this trend, helping businesses leverage the technology to gain competitive advantages.

The logistics industry provides compelling examples of this transformation. UPS has emerged as an early adopter, installing 3D printing workstations in its stores as early as 2015 through its investment in Fast Radius. The shipping giant further expanded its capabilities by adding a 3D printing facility at its Louisville, Kentucky hub.

In 2017, UPS partnered with SAP to develop an end-to-end 3D printing order solution capable of completing orders—from receipt through production and delivery—within a single day. This ambitious project underscores both companies' commitment to advancing 3D printing applications in logistics.

Building a 3D Printing Service Ecosystem

Both SAP and UPS aim to become preferred resources for businesses seeking to harness 3D printing's rapid prototyping and production capabilities. Their strategy extends beyond technology to creating comprehensive service ecosystems that support the entire production cycle from design to delivery.

The Future: Customization and Distributed Manufacturing

Looking ahead, 3D printing will play an increasingly vital role in supply chains as costs decrease and capabilities expand. Two key developments will shape this evolution:

- Mass customization: The ability to produce unique items tailored to individual preferences will create new market opportunities.

- Distributed manufacturing: Localized production will reduce lead times and transportation costs while increasing supply chain flexibility.

While challenges remain—including material limitations, equipment costs, and workforce training—these obstacles present opportunities for innovation. Companies that embrace additive manufacturing now will be best positioned to compete in the emerging smart manufacturing era.

The SAP-Stratasys partnership demonstrates how 3D printing represents more than technological advancement—it signals a fundamental shift in manufacturing philosophy. As industries adopt this transformative approach, we stand at the threshold of a more efficient, agile, and intelligent production future.