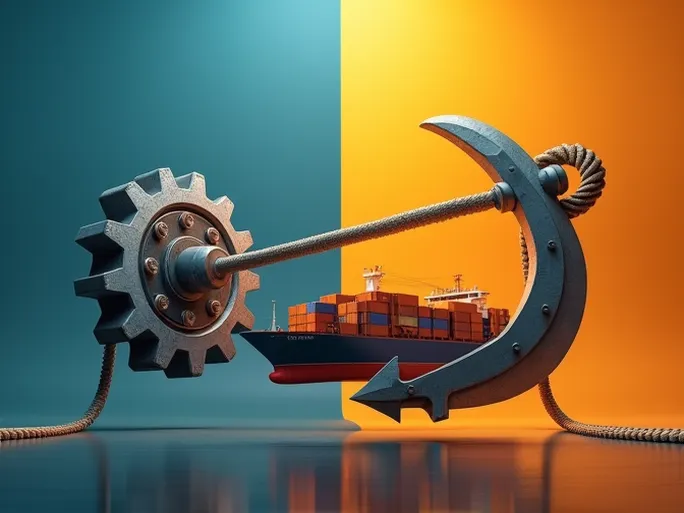

At the picturesque Port of Charleston in South Carolina, a quiet but significant battle over the future of port operations is unfolding. This confrontation isn't happening at the negotiating table but through a subtle yet noticeable tactic—a deliberate "slowdown" by dockworkers. This event represents more than an isolated labor dispute; it highlights the growing tensions between workers and management amid the global push for port automation, foreshadowing challenges that may reshape maritime operations worldwide.

Charleston's "Slowdown": Labor Resistance in the Shadow of Automation

Imagine the morning sun casting its glow over the Wando Welch Terminal in Charleston, where the usual bustling activity has been replaced by an unusual tension. Truck drivers wait in long lines, not for automated equipment but for manual chassis inspections—a deliberate action by the International Longshoremen's Association (ILA) protesting the port's automation upgrades.

Last Friday, ILA members insisted on performing manual chassis checks rather than using the newly installed automated video inspection system. This labor-intensive process created significant congestion and delays, with some truckers reportedly waiting hours to move their cargo. While the backlog was eventually cleared, the incident casts a shadow over upcoming labor negotiations and reveals deep concerns about automation's impact on dockworker jobs.

The timing was particularly notable, occurring just as the South Carolina Ports Authority planned to test automated inspection technology at a nearby terminal. The ILA's action directly reflects workers' fears that automation could eliminate their livelihoods—a concern grounded in observations of technology's disruptive effects across other industries.

Automation: Efficiency Booster or Job Killer?

The ILA's strong opposition stems from legitimate worries about potential job losses. In upcoming contract negotiations with the United States Maritime Alliance, the union has pointed to automation's role in reducing manufacturing jobs as a cautionary tale. Union leaders understand their leverage—the memory of costly West Coast port strikes remains fresh in the industry's mind.

Port operators face a dilemma. While automation technologies like robotic cranes, autonomous trucks, and smart warehouse systems promise greater efficiency and lower costs, they also threaten traditional dockworker roles. Without proper transition plans, automation could displace workers and exacerbate economic inequality.

Yet ports cannot ignore automation's benefits. Global trade growth demands faster cargo handling, and automated systems operate continuously without fatigue, potentially reducing errors and improving safety. The challenge lies in balancing these advantages with workforce protections.

Finding Common Ground: Training, Protections and Dialogue

The path forward requires compromise. The ILA might reconsider its stance if ports commit to:

- Comprehensive retraining programs: Helping workers develop skills for automated environments, from equipment operation to data analysis.

- Job security guarantees: Avoiding mass layoffs through reassignments, early retirement options, and upskilling initiatives.

- Open communication: Establishing regular discussions between labor and management to address concerns collaboratively.

- Equitable benefit sharing: Ensuring automation's cost savings improve wages and working conditions.

Global Perspectives: Lessons from Automated Ports

Charleston's situation mirrors international experiences:

- Rotterdam: Europe's largest automated port successfully transitioned through worker retraining and no-layoff pledges.

- Hamburg: Negotiated agreements directing automation's efficiency gains toward improved worker benefits.

- Singapore: Government-led training programs helped workers adapt to technological changes.

These examples demonstrate that automation need not create conflict when implemented thoughtfully.

The Road Ahead: Balancing Progress and People

Port automation represents both technological and socioeconomic challenges. Successful implementation requires cooperation between governments, companies, and unions to:

- Develop transparent communication channels

- Invest in workforce development

- Establish fair compensation structures

- Maintain safety and environmental standards

Charleston's slowdown serves as both warning and opportunity—a chance to build an automation model that benefits all stakeholders. The coming years will test whether ports can harness technology's potential while protecting their most valuable asset: skilled workers.