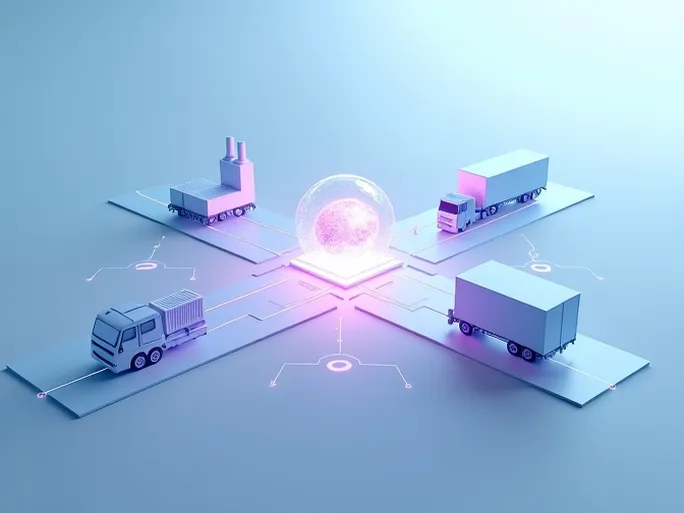

Imagine a global consumer electronics company with suppliers and distribution networks spanning four continents. Previously plagued by inaccurate demand forecasts, excess inventory, and shipping delays, the company struggled with rising costs and declining customer satisfaction. By implementing an AI-powered demand forecasting system, a blockchain-based traceability platform, and IoT-enabled real-time monitoring solutions, it successfully optimized its entire supply chain—reducing costs, improving efficiency, and enhancing customer experience. This isn't science fiction, but a real-world example of technology-driven supply chain transformation.

In today's competitive landscape, technological innovation has become a critical driver of business success. For supply chain management, the strategic adoption of emerging technologies not only solves existing challenges but also creates new opportunities for value creation.

1. Artificial Intelligence and Machine Learning: Predictive Analytics for Smarter Decisions

AI and ML are revolutionizing how supply chains forecast demand and make operational decisions. By analyzing vast amounts of historical data, market trends, and external factors, these algorithms deliver more accurate demand predictions, optimize inventory levels, and identify potential risks. This enables businesses to reduce excess stock, lower operational costs, and improve customer satisfaction through better product availability.

2. Blockchain Technology: Building Transparent and Trustworthy Networks

Blockchain's decentralized and immutable nature provides unprecedented transparency and traceability across supply chains. Companies can track products in real-time—from raw material origins through manufacturing processes to final delivery—helping prevent counterfeiting, enhance brand reputation, and comply with increasingly stringent regulatory requirements.

3. Internet of Things (IoT): Real-Time Monitoring and Smart Connectivity

IoT technologies, through sensors and RFID tags, enable continuous monitoring and data collection across supply chain operations. Businesses gain immediate visibility into inventory status, transportation conditions, and equipment performance, allowing faster response to disruptions, optimized resource allocation, and improved operational efficiency.

4. Cloud Computing and Big Data: Data-Driven Agility

Cloud platforms provide flexible, scalable IT infrastructure for supply chain operations, while big data analytics delivers powerful insights. By consolidating and analyzing data from multiple sources, companies gain deeper understanding of customer needs, improve product design, and accelerate supply chain responsiveness.

5. Automation and Robotics: Efficiency Gains Through Intelligent Systems

The application of automation and robotics in warehousing, transportation, and manufacturing significantly boosts productivity while reducing costs. Automated guided vehicles (AGVs), robotic sorting systems, and collaborative robots are increasingly replacing manual processes—minimizing human error and enhancing production efficiency.

These disruptive technologies are fundamentally reshaping modern supply chain operations. Businesses that proactively embrace these innovations and develop tailored digital transformation strategies will be best positioned to thrive in an increasingly competitive marketplace.