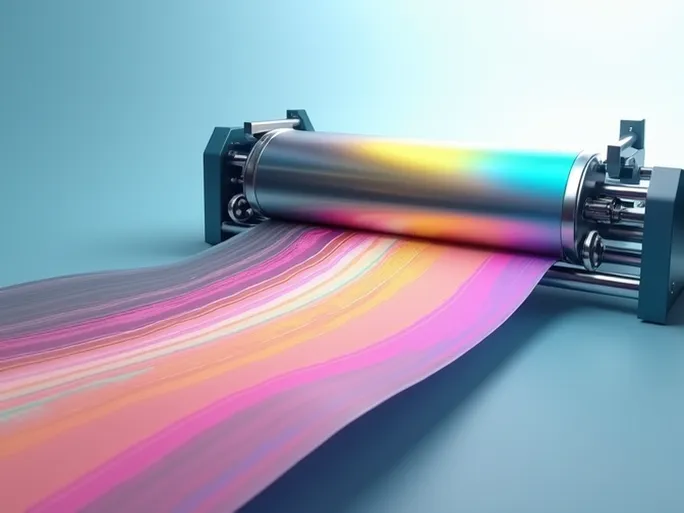

The printing industry has long grappled with challenges surrounding coated paper production, particularly concerning slow drying speeds, high energy consumption, and environmental compliance pressures. A new generation of digital inkjet rotary printing machines now offers comprehensive solutions to these persistent issues.

Advanced Drying Technology Enhances Production Efficiency

Modern printing systems incorporate intelligent infrared heating with air circulation technology, separating printing and drying processes while enabling precise temperature control and dynamic moisture removal. This technological advancement effectively manages moisture levels within the system, accelerating ink drying and significantly improving production efficiency.

Traditional printing methods often suffer from extended drying periods that delay production cycles and order fulfillment. The new drying technology optimizes the entire process, reducing waiting times and substantially improving order turnover. Additionally, it ensures superior ink adhesion, enhancing both the durability and quality of printed materials.

Specialized Quick-Drying Inks Improve Performance

Complementing the advanced drying system, specially formulated quick-drying inks have been developed. These proprietary ink formulations work synergistically with infrared heating technology to rapidly form durable ink layers that achieve immediate drying. The inks demonstrate exceptional deep-layer adhesion, forming strong bonds with coated paper surfaces to resist abrasion and maintain visual appeal.

The colorfast properties of these inks ensure long-term vibrancy, preventing fading and maintaining optimal visual quality throughout the product lifecycle. This represents a significant advancement over conventional ink technologies that often degrade over time.

Environmentally Conscious Production Methods

The infrared heating and air circulation system addresses two critical industry concerns: energy efficiency and environmental impact. This innovative approach substantially reduces power consumption compared to traditional drying methods, resulting in meaningful energy cost savings.

The technology has received environmental certification, with volatile organic compound (VOC) emissions meeting stringent national standards. This compliance enables printing operations to align with increasingly rigorous environmental regulations while pursuing sustainable business practices.

Versatile Applications and Operational Simplicity

The digital printing systems demonstrate particular effectiveness for educational materials, examination papers, publications, and artistic portfolios requiring high-quality coated paper output. The equipment features intuitive operation with automatic parameter adjustment capabilities, minimizing the need for manual configuration.

This user-friendly design reduces dependence on highly skilled technicians, addressing workforce challenges in the printing industry while maintaining production quality standards. The technology's adaptability makes it suitable for diverse printing applications with varying requirements.

Technical Expertise and Industry Experience

The technology behind these systems stems from two decades of specialized research and development in printing technologies. The development company holds numerous core patents covering comprehensive printing processes, ensuring technological leadership in the field.

With extensive practical experience serving thousands of clients globally, the technology has been refined through real-world application across diverse printing scenarios. This accumulated expertise informs continuous improvements and specialized solutions for industry challenges.

The availability of complimentary paper testing services allows potential users to evaluate print quality firsthand before making investment decisions. This practical demonstration approach underscores confidence in the technology's capabilities and its potential to transform coated paper printing operations.