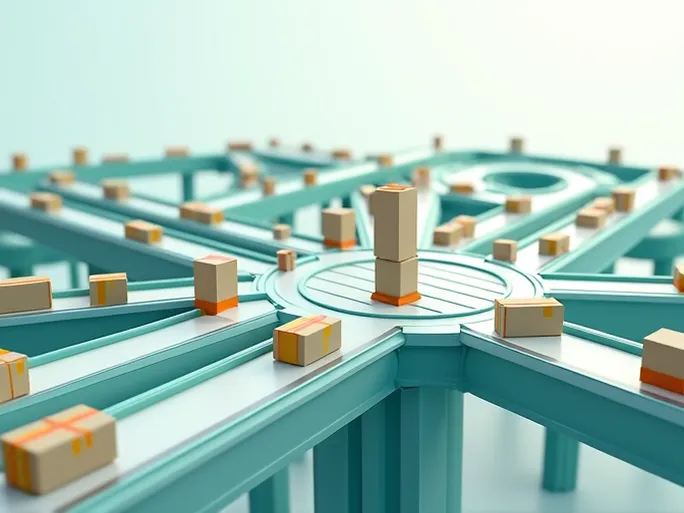

Picture a warehouse overflowing with packages, the clock ticking relentlessly as customer deadlines loom, while your logistics system creaks along like an overloaded trailer. This scenario represents the harsh reality many businesses face during the year-end holiday shopping season. The question remains: how can companies avoid this predicament, transforming challenges into opportunities to enhance material handling efficiency and earn customer trust?

The holiday season serves as an intense stress test for logistics operations. Data from weeks 49 and 50 of 2019 reveals that even with generally stable on-time delivery rates, carriers face formidable challenges during seasonal peaks. Looking ahead to 2025, logistics management will continue navigating persistent volatility, policy fluctuations, and uneven demand patterns. Uncertainty permeates every aspect—from tariffs to trucking, rail transport to ocean shipping—with disruptive forces emerging at every turn.

Strategies for Peak Season Success

To excel during this annual trial, businesses must prioritize advance planning, optimized material handling processes, and overall operational efficiency improvements. Several key areas demand attention:

- Automation and Intelligent Upgrades: Implementing automated material handling systems—including AGVs (Automated Guided Vehicles), stacker cranes, and conveyor systems—can dramatically improve warehouse efficiency while reducing human error. Smart Warehouse Management Systems (WMS) enable precise inventory control and optimization, ensuring rapid and accurate order processing.

- Data-Driven Demand Forecasting: Leveraging big data analytics to examine historical sales patterns, market trends, and customer behavior allows for accurate demand predictions. These insights enable proactive inventory adjustments and logistics route optimization. Real-time monitoring helps identify and resolve potential issues before they cause delays or bottlenecks.

- Agile Supply Chain Development: Building flexible supply networks capable of rapid adaptation to market shifts and disruptions proves critical. Establishing relationships with multiple carriers ensures adequate capacity during peak periods. Simultaneously, optimizing warehouse layouts maximizes space utilization for increased inventory storage.

- Lean Process Optimization: Applying lean management principles to material handling processes eliminates waste and improves efficiency. Standardized workflows reduce redundant tasks and lower operational costs. Comprehensive employee training ensures proficiency with equipment and systems.

The holiday season presents both challenges and opportunities. Only enterprises that prepare strategically, streamline material handling, and enhance operational efficiency will emerge successfully from this competitive crucible—earning customer loyalty while achieving sustainable growth.