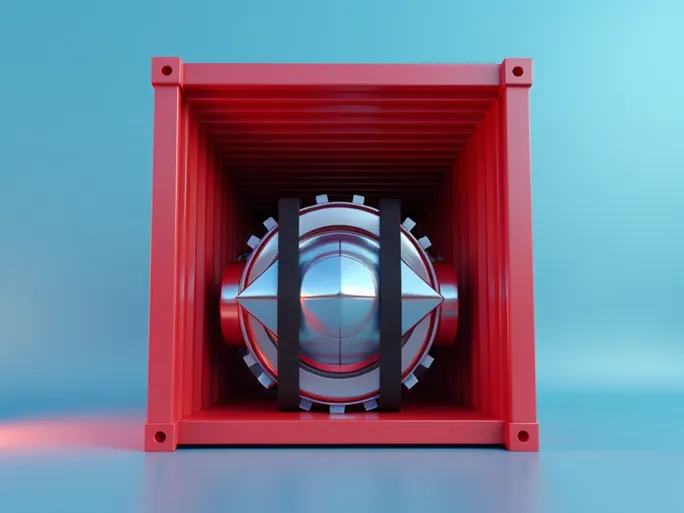

When conventional shipping containers cannot accommodate oversized, overweight, or irregularly shaped goods, specialized containers emerge as reliable solutions for cross-border transportation. This article examines the types of specialized containers for European maritime shipping, their optimal applications, and operational best practices.

Specialized Containers: Tailored Solutions for Unique Requirements

Specialized containers are expressly designed to transport cargo exceeding standard container dimensions or weight limitations. These units efficiently accommodate large machinery, extended steel beams, yachts, and other items incompatible with regular containers. European maritime specialized container services specifically address import/export needs for such exceptional cargo.

Four Primary Specialized Container Types and Their Applications

Specialized containers are categorized into four principal types based on cargo characteristics and loading methods:

- Open Top Containers: Featuring removable tops, these units suit height-restricted cargo requiring vertical loading, such as industrial equipment. Overhead crane loading significantly enhances operational efficiency.

- Flat Rack Containers: With removable sidewalls and open tops, these containers accommodate width- or height-restricted cargo needing lateral loading, including marine vessels and wide structural components. Their design facilitates horizontal loading via forklifts or cranes.

- Platform Containers: Consisting solely of load-bearing floors with detachable end frames, these units transport exceptionally long or heavy items like pipelines and steel beams, offering simplified loading and securing capabilities.

- Refrigerated Containers: Temperature-controlled units preserve perishable commodities including foodstuffs, pharmaceuticals, and chemicals throughout transit, maintaining product integrity.

Operational Best Practices for Specialized Container Shipping

Successful specialized container transportation requires meticulous planning and professional execution. Key operational considerations include:

Booking Procedures: Advance coordination with shipping lines is essential to confirm container specifications, quantities, and schedules. Detailed cargo information—including precise dimensions, weight, and packaging—enables carriers to develop appropriate transport solutions.

Loading and Securement: Proper packaging materials and loading techniques ensure cargo stability during transit. Utilize strapping, lashing systems, and wooden bracing to immobilize goods within containers, with particular attention to weight distribution to prevent tipping hazards.

Transit Monitoring: Carefully plan transport routes and methods to guarantee timely delivery. Implement GPS tracking to identify potential disruptions like traffic congestion or adverse weather conditions.

Unloading Protocols: Supervise unloading operations to ensure cargo safety. Conduct thorough inspections against shipping manifests, documenting any discrepancies immediately upon discovery.

Critical Considerations for Successful Operations

Additional factors requiring attention when shipping specialized containers to Europe include:

Dimensional Allowances: Incorporate adequate clearance margins when selecting containers, accounting for packaging materials and securing apparatus to prevent loading complications.

Transport Limitations: Certain specialized containers may have weight restrictions or route constraints. Research port-specific regulations regarding oversized cargo to select appropriate transit paths.

Customs Compliance: Specialized container shipments typically require dedicated customs declarations with accurate commodity descriptions and tariff codes. Prepare documentation in advance to prevent clearance delays.

Through comprehensive understanding of specialized container characteristics and operational requirements, businesses can effectively transport non-standard cargo to European markets, facilitating international trade expansion.