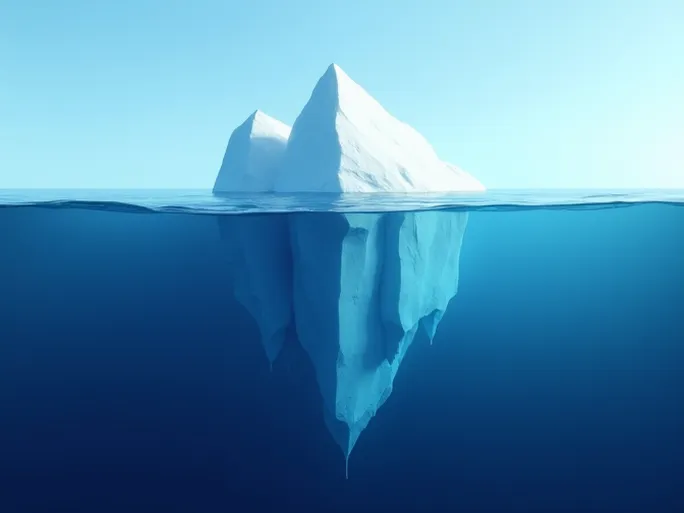

Many Amazon sellers face a frustrating paradox: while their sales numbers grow, profit margins remain stagnant. The culprit? Amazon's FBA (Fulfillment by Amazon) fees - a complex web of charges that often operates like a black box. This investigative analysis breaks down FBA cost structures through a data analyst's lens and provides actionable optimization strategies to maximize profitability.

The Hidden Architecture of FBA Fees

Amazon's fulfillment costs aren't a single charge, but rather a layered system comprising multiple fee categories. Understanding this structure is the first step toward financial optimization.

FBA Handling Fees: The Silent Profit Drain

These fees cover Amazon's processing activities including sorting, scanning, weighing, and packaging your inventory. While individual handling fees appear nominal, they accumulate significantly across high-SKU catalogs or frequent shipments.

Optimization Tactics:

- Redesign packaging to minimize dimensional weight and materials

- Consolidate shipments to reduce processing frequency

- Ensure perfect product data accuracy to avoid manual interventions

FBA Shipping Costs: The Last-Mile Calculation

Shipping fees vary based on product dimensions, weight, and destination. Amazon's tiered shipping matrix creates critical inflection points where minor adjustments can yield substantial savings.

Optimization Tactics:

- Engineer products to fit lower dimensional tiers

- Leverage Amazon's Small and Light program for eligible items

- Monitor shipping policy updates for new cost-saving opportunities

Storage Fees: The Inventory Balancing Act

Warehousing costs fluctuate seasonally, with Q4 rates typically spiking 40-50%. Fees compound based on both cubic footage and storage duration, making inventory velocity paramount.

Optimization Tactics:

- Implement AI-driven demand forecasting to prevent overstocking

- Utilize Amazon's Inventory Performance Index dashboard

- Consider hybrid fulfillment models for slow-moving inventory

Ancillary Charges: The Fine Print Matters

Secondary fees including returns processing, removal orders, and disposal fees can unexpectedly erode margins when unmanaged.

Optimization Tactics:

- Enhance product quality and listing accuracy to minimize returns

- Implement proactive inventory liquidation strategies

- Establish return analysis protocols to identify recurring issues

Data-Centric Optimization Framework

True cost control requires moving beyond basic awareness to implement analytical systems:

- Develop granular fee tracking by ASIN across all cost categories

- Conduct Pareto analysis to identify your 20% of SKUs generating 80% of fees

- Benchmark your cost structure against category averages

- Implement A/B testing for packaging and fulfillment variations

- Establish monthly cost review cadences with performance metrics

Case Study: Packaging Engineering Delivers 22% Savings

A home goods seller reduced their FBA shipping costs by redesigning product packaging to fit a lower dimensional tier. The $0.38 per-unit savings translated to $19,000 annualized margin improvement across their catalog.

The Path to Profitability

Mastering FBA economics requires continuous optimization. By combining structural fee knowledge with analytical rigor, sellers can transform fulfillment costs from a profit drain to a competitive advantage.