As the massive vessels of global trade navigate the world's oceans, shipping containers serve as the indispensable standardized cargo units aboard these ships. These seemingly uniform "steel boxes" are actually meticulously categorized into various types based on the characteristics of the goods they carry. Selecting the appropriate container not only concerns cargo safety but directly impacts transportation efficiency and costs. What types of containers exist in international shipping, and what specific purposes do they serve?

1. Dry Containers: The Workhorse of General Cargo

Dry containers, also known as general purpose containers, are the most widely used type in international shipping, accounting for 70-80% of all containers. They primarily transport goods requiring no special temperature or humidity control, including stationery, daily necessities, textiles, electronics, and mechanical parts. Any cargo that meets standard container dimensions and weight requirements—excluding frozen goods, live animals, or plants—can be shipped in dry containers. Their universal applicability makes them the most familiar "face" of international trade.

2. Reefer Containers: The Freshness Guardians

For temperature-sensitive goods requiring constant refrigeration, reefer containers provide the optimal solution. These come in two variants: externally refrigerated units that depend on specialized vehicles, vessels, or port facilities for cooling, and self-contained units with independent refrigeration systems capable of maintaining temperatures between -60°C and +30°C. Reefer containers are essential for transporting perishables like butter, chocolate, frozen fish, and condensed milk, playing a critical role in food safety and quality preservation.

3. Open-Top Containers: The Vertical Solution

Characterized by their removable roof structures—typically replaced by foldable roof bows and waterproof tarpaulins—open-top containers facilitate top-loading via cranes. This design makes them ideal for oversized or irregularly shaped cargo like glass panels, steel products, and heavy machinery that cannot be loaded through standard container doors. After loading, the waterproof cover ensures equivalent watertight protection to dry containers.

4. Flat Rack Containers: The Heavy-Duty Specialists

Flat rack containers eliminate side walls and roofs, retaining only base structures and end frames to enable side loading. Engineered specifically for overweight cargo, they also accommodate livestock or unpackaged goods like steel products. Their primary advantage lies in handling oversized, extra-wide, or exceptionally tall shipments that exceed conventional container limitations.

5. Livestock Containers: Mobile Animal Habitats

Designed for transporting cattle, horses, and other live animals, these specialized containers feature metal mesh sides for optimal ventilation and caretaker access. They incorporate animal welfare considerations into their design, providing humane solutions for international livestock transport.

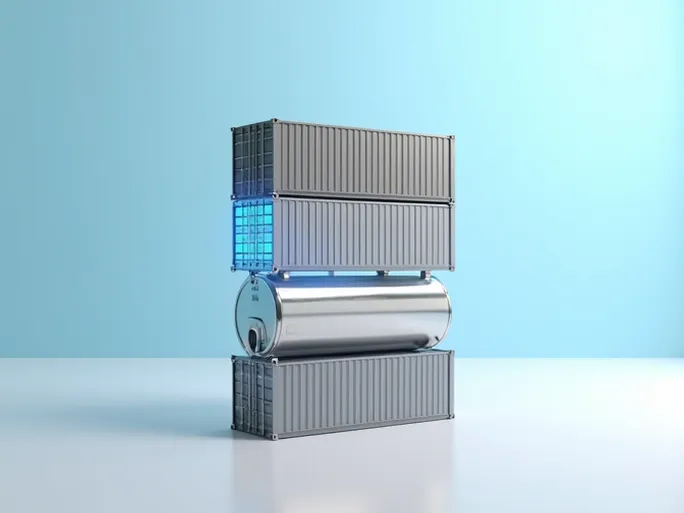

6. Tank Containers: Liquid Cargo Security

Tank containers specialize in transporting liquid commodities like food products, pharmaceuticals, and chemicals. Their core component is a stainless steel tank (typically 316-grade for corrosion resistance) mounted within a steel frame. Optional features include heating systems, inert gas protection, and pressure regulation devices to ensure safe liquid transport under various conditions.

7. Platform Containers: The Heavyweight Champions

Resembling railroad flatcars, platform containers consist solely of reinforced bases without superstructures. They accommodate exceptionally long or heavy cargo—items exceeding 6m in length, 4m in width, 4.5m in height, or weighing up to 40 metric tons. Two interconnected platforms can support loads up to 80 metric tons. These containers are particularly valuable for automobile shipping.

8. Ventilated Containers: The Produce Preservers

Featuring 4-6 ventilation ports and plastic-coated interiors, these containers maintain airflow for temperature-sensitive agricultural products like fresh fruits and vegetables. The ventilation system prevents humidity buildup and overheating that could cause spoilage during transit.

9. Insulated Containers: Temperature-Regulated Transport

With insulated walls and adjustable roof vents, these containers modulate internal temperatures using external air currents. When sealed completely, they maintain stable conditions for sensitive chemical or pharmaceutical shipments requiring precise climate control.

10. Bulk Containers: Granular Cargo Solutions

Designed for unpackaged commodities like grain or cement, bulk containers feature top loading hatches and tiltable bases (up to 40°) for gravity-assisted unloading. Some models include fumigation capabilities to meet phytosanitary requirements.

11. Powder Bulk Containers: Dust-Free Powder Transport

Similar in structure to standard bulk containers but employing specialized pneumatic loading/unloading systems via pipes, these units minimize dust dispersion during powder cargo handling.

12. Garment Containers: The Fashion Forward Solution

Equipped with hanging systems to prevent garment wrinkling, these specialized containers maintain clothing presentation quality throughout international transit, serving the apparel industry's unique shipping needs.

As global trade evolves and commodity diversity increases, new specialized or multi-purpose container types will continue emerging to meet growing transportation demands. Understanding container characteristics and selecting the optimal type for specific cargo remains fundamental to efficient, cost-effective international shipping.