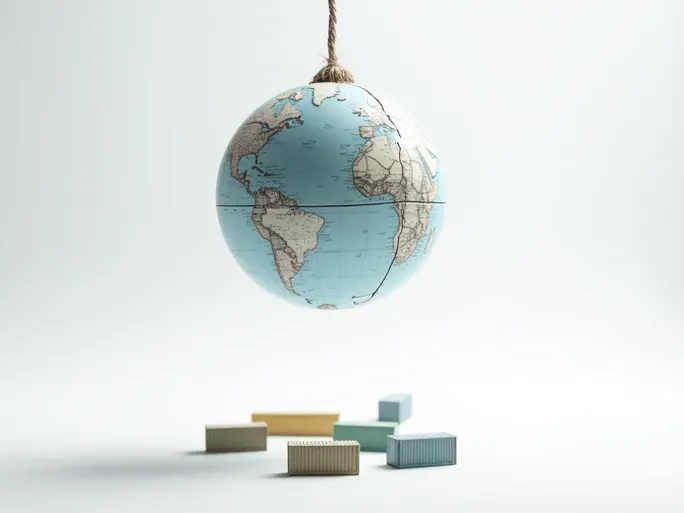

Imagine this: urgently needed medical equipment fails to reach a distant hospital during its critical window due to flight delays. Priceless artworks arrive damaged beyond repair after rough handling during transit. International air transport—the vital "aerial lifeline" connecting global commerce—doesn't always operate smoothly. When cargo fails to arrive at the right time, place, or in proper condition, cross-border trade faces what the industry calls "irregular transport." What causes these disruptions, and how can stakeholders safeguard air freight's efficiency and reliability?

The Hidden Risks of Irregular Air Transport

In international air cargo, "irregular transport" doesn't refer to isolated incidents but encompasses all deviations from standard procedures that compromise delivery. The core issue arises when goods fail to meet the terms specified in the air waybill (AWB) or transport agreement—whether in timing, location, or condition. The International Air Transport Association (IATA) defines it as anomalies occurring throughout the entire shipping process, from acceptance to delivery, commonly manifesting as delays, damage, loss, misrouting, or missed loading.

Six Types of Irregularities: Identifying Risk Points

The international air cargo chain involves multiple stages—dispatch, warehousing, loading, transport, unloading, customs clearance, and final delivery—with vulnerabilities at each step. Here are six common irregularity types:

-

Delays: Racing Against Time

Delays occur when cargo arrives later than contractually agreed or when carriers fail to deliver within reasonable timeframes. Causes include weather-related flight cancellations, sorting delays at transit hubs missing connecting flights, or prolonged customs inspections. -

Damage: A Fragile Journey

Goods may suffer physical harm from crushing, impact, moisture, or excessive heat during transit—resulting in cosmetic defects, functional failures, or diminished value. Examples include poorly packaged fragile items shattering, electronics damaged by high cabin temperatures, or leaking liquids contaminating other cargo. -

Loss or Shortage: Missing Goods, Elusive Accountability

Shortages describe deliveries with fewer items than declared on the AWB, while loss refers to untraceable entire shipments. Causes range from misrouted parcels during sorting to theft in transit or tracking errors creating "false losses" that manual searches could resolve. -

Misrouting or Missed Loading: Off-Course Shipments

Misrouted cargo reaches incorrect destinations, while missed loading leaves goods stranded at origin or transit points. Common causes include mislabeled destination tags or flight overloading forcing deferred shipments. -

Unclaimed Cargo: Forgotten Shipments

Goods languish at destination airports when recipients refuse delivery, become unreachable, or fail customs clearance. Reasons include market-driven rejections (e.g., depreciated goods), incomplete clearance documentation, or hazardous material declaration discrepancies leading to abandonment. -

Special Circumstances: Unforeseen Risks

Additional risks include misdeclared cargo (e.g., undeclared hazardous materials halting transport) or AWB errors (incorrect recipient details preventing delivery).

Root Causes: Why Irregularities Occur

Irregular transport rarely stems from single factors but emerges from compounded responsibilities or systemic gaps:

-

Shipper Responsibility: Source Control Matters

Improper packaging, inaccurate declarations (description, quantity, weight, HS codes), or missing documentation can trigger downstream issues. -

Carrier/Ground Handler Accountability: Operations Define Outcomes

Handling errors (mis-sorting, labeling mistakes, loading omissions), equipment failures, or IT system glitches disrupt operations. -

External Forces: Unpredictable Challenges

Natural disasters, geopolitical unrest, strikes, sudden customs restrictions, or air traffic controls create unavoidable disruptions. -

Freight Forwarder Liability: Coordination is Key

Poor communication (delayed flight updates or clearance reminders) or subpar partner selection (unqualified ground handlers) contribute to failures. -

Cross-Border Complexity: Multinational Vulnerabilities

Divergent national regulations, language barriers, and logistics standards across origin, transit, and destination countries create operational gaps.

The Cost of Irregularities: Multilateral Consequences

Irregular transport creates ripple effects across supply chains:

- Owners (Shippers/Consignees): Face direct financial losses plus reputational harm from damaged goods, contractual penalties, or eroded client trust.

- Carriers: Incur compensation costs under the Warsaw/Montreal Conventions while suffering brand damage that may reduce market share.

- Forwarders: Experience client attrition and increased operational costs from dispute resolution, sometimes requiring upfront compensation before recovering from liable parties.

- Supply Chains: Suffer systemic inefficiencies from stranded goods causing production halts or inventory pileups.

Managing Irregularities: From Detection to Resolution

Effective response protocols include:

- Detection & Notification: Stakeholders identify anomalies via tracking systems, immediately alerting carriers or handlers; carriers should proactively notify affected parties.

- Liability Determination: Gather evidence (AWBs, cargo photos, packaging records, delay certificates) to assign responsibility—shippers bear costs for packaging failures, carriers for operational errors, while force majeure events warrant shared solutions.

- Loss Assessment & Cargo Disposition: Owners provide value proof; third parties evaluate damage. Options include repair, destruction, or return. Misrouted goods require rerouting at the responsible party's expense.

- Claims Processing: Parties negotiate settlements; unresolved cases proceed to litigation per transport contracts or conventions. Cargo insurance may cover eligible losses.

Prevention: Collaborative Safeguards

Proactive measures reduce irregular transport risks:

- Shippers: Use appropriate packaging with clear handling labels; declare contents accurately; verify recipient clearance requirements beforehand.

- Carriers/Handlers: Standardize operating procedures; deploy IoT tracking and environmental sensors; train staff rigorously.

- Forwarders: Monitor shipments in real-time; partner with reputable service providers; maintain transparent client communication.

- Industry: Adopt blockchain for end-to-end transparency; harmonize international customs and logistics standards.

Case Example: Packaging Failure

An exporter shipped ceramic tableware to Europe using only cardboard—no cushioning—to cut costs. Rough handling during transit shattered 80% of items. Since the shipper violated IATA Packaging Guidelines for fragile goods, they bore full responsibility, replacing the shipment while the carrier faced no liability.

Ultimately, irregular air transport stems from procedural gaps and information asymmetries. Shippers must prioritize source control, logistics providers need technological and operational upgrades, while global standardization efforts can enhance transparency. Only through coordinated action can the industry minimize disruptions, ensuring air cargo remains a reliable pillar of global trade.