Loading cargo into international shipping containers is far more complex than simple stacking. It represents a sophisticated technical process involving cargo safety, space optimization, and cost control. Proper loading strategies not only maximize container capacity and reduce per-unit transportation costs but also effectively protect goods from damage caused by collisions or compression during long-distance shipping. This article systematically explains key aspects and considerations of international container loading, providing professionals with a comprehensive and practical operational guide.

1. Thorough Pre-Loading Planning

Before loading, detailed analysis of all cargo attributes is essential, including:

- Dimensions and Weight: Precise measurements of length, width, height, and weight for each item form the foundation of loading plans, directly impacting space utilization and weight distribution.

- Shape: Regular-shaped items are easier to stack, while irregular shapes require special placement techniques to minimize wasted space.

- Characteristics: Different cargo types have varying physical and chemical properties (fragile, flammable, moisture-sensitive, etc.) that determine necessary protection and isolation measures.

- Destination and Delivery Timeline: Loading sequence should be arranged according to final destinations and estimated delivery times, with items needing earlier unloading placed near container doors.

After cargo analysis, detailed loading plans should be developed based on container interior dimensions and weight limits. These plans should specify placement positions, stacking methods, securing techniques, and required padding materials. For large or irregularly shaped items, 3D modeling software can simulate loading scenarios to optimize space usage.

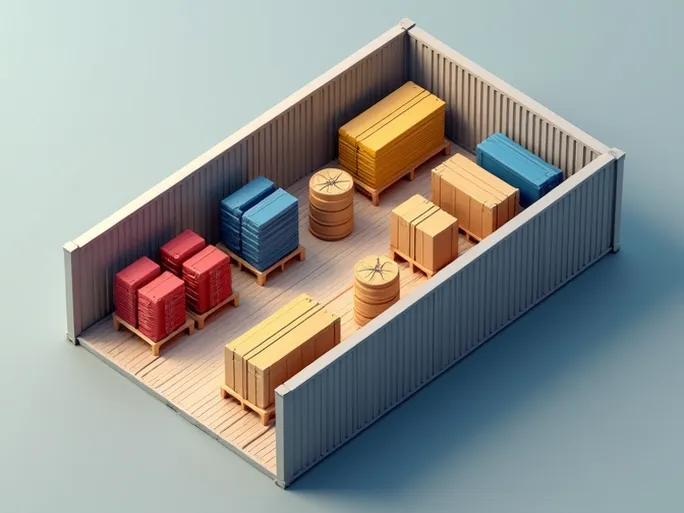

2. Optimal Container Space Utilization

Common international shipping containers include:

- 20-foot Standard: ~33 cubic meters capacity, ~28-ton payload

- 40-foot Standard: ~67 cubic meters capacity, ~26-ton payload

- 40-foot High Cube: ~76 cubic meters capacity, ~26-ton payload

Key space optimization techniques include:

- Palletization: Consolidating small items onto pallets improves loading efficiency and reduces movement during transit.

- Padding: Filling gaps with foam boards, air cushions, or cardboard prevents shifting while maximizing space usage.

- Stacking: Vertical stacking utilizes container height, with attention to weight-bearing capacities to prevent damage.

- Hanging: Suitable for garments to prevent wrinkling and save space.

3. Effective Cargo Protection

Essential protection measures include:

- Shock Absorption: Multi-layer protection for fragile items using soft wrapping, custom foam casings, and central placement within containers.

- Moisture Prevention: Desiccants and moisture barriers for humidity-sensitive goods, with specialized containers for temperature control when needed.

- Theft Prevention: Security cameras, high-strength locks, and transport insurance for valuable items.

- Securing: Using ropes, straps, wedges, or chains to immobilize cargo, especially heavy items.

4. Selecting Loading Methods

Common on-site loading approaches:

- Shipper-Loaded: Offers maximum control but requires expertise and resources.

- Freight Forwarder Arranged: Professional handling with efficiency benefits but potential quality risks.

- Port/Depot Loading: Fast and specialized but offers less oversight.

5. Post-Loading Verification

Final checks should confirm proper securing and document:

- Loading date/time

- Container number

- Detailed cargo manifest

- Photographic evidence of loading

Mastering international container loading requires specialized knowledge and experience. Proper techniques enhance space utilization, ensure cargo safety, and reduce transportation costs - critical advantages in competitive global markets.