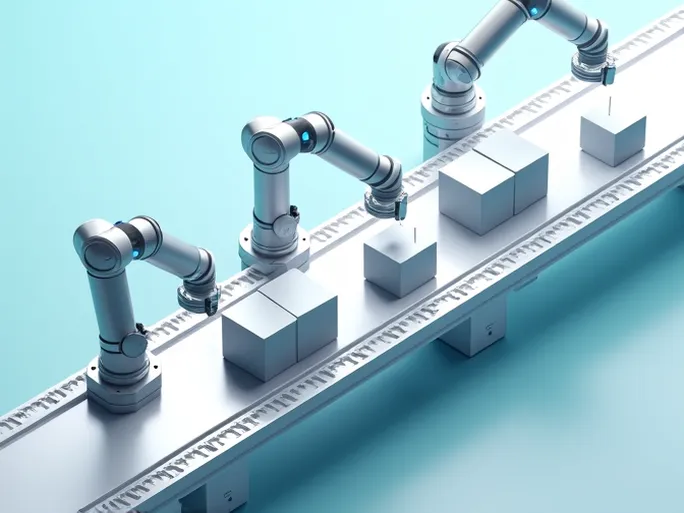

A groundbreaking collaboration between DHL Supply Chain, Microsoft, and Blue Yonder has produced an innovative "plug-and-play" robotics platform that promises to transform warehouse automation. This new solution addresses critical challenges facing the logistics industry while offering unprecedented flexibility and efficiency.

Industry Challenges Addressed

The logistics sector faces numerous obstacles that this platform specifically targets:

- Escalating labor costs that significantly impact profit margins

- Inefficient manual processes struggling to meet growing customer demands

- Complex and costly robot integration processes

- Inflexible operations unable to adapt to market fluctuations

- Limited capabilities for intelligent operational optimization

Platform Features and Benefits

Built on Microsoft Azure IoT and cloud platform services, the solution utilizes standardized interfaces and predefined workflows to dramatically reduce implementation time and complexity.

1. Rapid Deployment and Cost Reduction

The platform eliminates traditional integration challenges through its modular design. Instead of requiring weeks or months of specialized programming, warehouses can achieve full automation in days or even hours.

2. Enhanced Flexibility and Scalability

Operations can quickly adapt to changing market conditions by easily adding or modifying robotic systems. This agility allows businesses to respond to evolving customer requirements without major infrastructure changes.

3. Optimized Workforce Allocation

By automating repetitive tasks, human workers can focus on higher-value activities such as process optimization, problem resolution, and innovation development.

4. Operational Efficiency Improvements

The platform delivers measurable gains across multiple warehouse functions:

- Faster and more accurate picking operations

- Streamlined packaging processes

- Improved sorting accuracy

- Enhanced transportation efficiency

5. Multi-Vendor Compatibility

The solution supports integration with robotic equipment from various manufacturers, enabling customized automation configurations tailored to specific operational needs.

Proven Implementation

The platform has already demonstrated its effectiveness at a DHL Supply Chain facility in Madrid, Spain, where it significantly reduced integration complexity and accelerated deployment of robotic systems with existing warehouse management infrastructure.

"Our goal was to build an industry-reusable solution with predefined workflows and standardized API interfaces. Warehouses looking to augment their workforce with automation will benefit tremendously from this robotics hub."

— Prabodh Joshi, Senior Product Director at Blue Yonder

"Automation and collaborative robots help make our operations more flexible and ergonomic while creating more engaging work for our employees. Our objective isn't workforce replacement, but rather enabling our staff to focus on more rewarding tasks."

— Markus Voss, Global CIO and COO of DHL Supply Chain

Technical Foundation

The platform leverages Blue Yonder's Luminate Platform with its machine learning-powered task management capabilities, combined with Microsoft Azure IoT services. This technical foundation ensures high-performance warehouse operations while maintaining standardized integration capabilities across robotic systems.

Industry Impact

This innovation arrives as logistics companies increasingly seek automation solutions to address rising labor costs and growing demand for faster, more reliable delivery services. The platform's ease of deployment and cost-effectiveness positions it as a potential catalyst for widespread industry transformation.

Industry analysts view the collaboration as a significant milestone in logistics automation, solving critical integration challenges that have previously hindered robotic adoption in warehouse environments.

Future Development

The partner companies plan continued enhancements to expand the platform's capabilities, including support for additional robotic types, advanced task management features, and deeper integration with broader supply chain management systems.