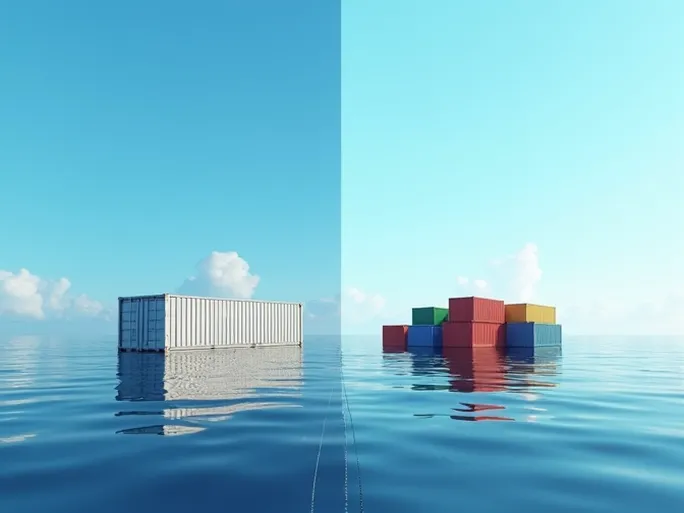

When shipping goods across oceans, businesses face a critical decision: should they opt for Full Container Load (FCL) shipping, akin to a private charter, or Less than Container Load (LCL) shipping, similar to a group booking arrangement? This choice involves complex booking procedures, cost considerations, and potential risks that can significantly impact supply chain efficiency.

I. FCL Shipping: Your Exclusive "Ocean Freight Express"

FCL shipping means exclusively using an entire container for your cargo. This method offers greater autonomy and a more streamlined process from booking to delivery.

1. Booking Application and Space Confirmation

The process begins with submitting a detailed booking request to a freight forwarder, which should include:

- Accurate shipper and consignee information

- Comprehensive goods description for customs compliance

- Package count, gross weight, and volume measurements

- Container type selection (20GP, 40GP, or 40HQ)

- Port of loading and destination details

- Preferred sailing schedule

Upon approval, the shipping line issues a Shipping Order (S/O) containing vessel details, cutoff times, and container pickup location. The S/O serves as official space confirmation.

2. Container Pickup and Loading

With the S/O, shippers collect empty containers from designated depots. Loading can be performed at the shipper's facility or through professional warehouses. After loading, containers must be sealed with recorded container and seal numbers for customs documentation.

3. Container Return and Export Customs

Loaded containers (referred to as "full container loads") return to the port for vessel loading. Export customs clearance requires submission of packing lists, commercial invoices, contracts, and container details before the customs cutoff time.

4. Documentation Submission and Bill of Lading

Before documentation deadlines, shippers must provide complete Bill of Lading (B/L) information. Shipping lines issue either Master Bills (direct from carrier) or House Bills (through forwarders). The telex release option allows electronic document transmission instead of physical B/Ls.

5. Vessel Departure and Destination Procedures

After loading and departure, consignees use original B/Ls (or telex release authorization) to obtain delivery orders, complete import clearance, and arrange final container pickup and unpacking.

II. LCL Shipping: Cost-Effective "Group Shipping"

LCL consolidates multiple shippers' cargo in single containers, ideal for smaller shipments under 15 cubic meters.

1. Booking and Cargo Consolidation

Forwarders assess shipment volumes before booking full container space with carriers. Shippers receive consolidation warehouse details and local charge breakdowns.

2. Cargo Collection and Consolidated Loading

Shipments undergo weighing, measurement, and labeling at consolidation warehouses before combined loading into shared containers with recorded sealing information.

3. Customs and Port Procedures

Forwarders handle consolidated customs declarations (or individual filings if required) before returning full containers to ports for loading.

4. Dual Bill of Lading Process

Forwarders receive Master Bills from carriers (listing their destination agents as consignees) while issuing separate House Bills to individual shippers showing actual consignees.

5. Destination Handling

At destination ports, forwarders' agents manage container unpacking and cargo separation. Consignees present House Bills (paying various handling fees) to obtain delivery orders before collecting goods from deconsolidation warehouses.

III. Key Differences Between FCL and LCL

| Factor | FCL | LCL |

|---|---|---|

| Operation Control | Shipper-directed | Forwarder-managed |

| Loading Process | Exclusive container loading | Consolidated loading |

| Customs Clearance | Individual declarations | Typically consolidated |

| Documentation | Carrier or forwarder bills | Forwarder bills only |

| Destination Process | Direct container pickup | Cargo separation required |

| Cost Structure | Transparent pricing | Complex fee breakdown |

| Transit Time | Faster | Slower |

| Cargo Risk | Lower | Higher |

IV. Selection Criteria: Volume, Cost, and Speed

The optimal choice depends on three primary factors:

- Shipment Volume: FCL becomes economical when filling entire containers; LCL suits smaller quantities

- Cost Considerations: FCL offers predictable pricing while LCL involves variable destination charges

- Time Sensitivity: FCL provides faster transit; LCL requires additional consolidation/deconsolidation time

FCL shipping best serves large-volume shipments requiring speed and control, while LCL benefits cost-conscious shippers with smaller, time-flexible cargo.