The third-party logistics (3PL) industry stands at the precipice of transformation. Traditional models, strained by pandemic disruptions and evolving market demands, are giving way to automated, data-driven solutions that promise unprecedented efficiency and resilience.

The Pandemic as Catalyst

COVID-19 exposed critical vulnerabilities in conventional supply chains while accelerating e-commerce growth. Michael Gravier, associate professor of marketing and supply chain management at Bryant University, observes that even before the pandemic, trade tensions and material shortages had already pushed companies to outsource logistics operations to 3PL providers.

"The crisis amplified 3PLs' strategic role in resource coordination," Gravier notes. "Providers must now evolve beyond basic fulfillment into true strategic partners."

Bridging the Trust Gap

A persistent challenge remains the disconnect between shippers and 3PL providers. Information asymmetry often leads to inefficient collaborations, with clients questioning operational methods while remaining dependent on them.

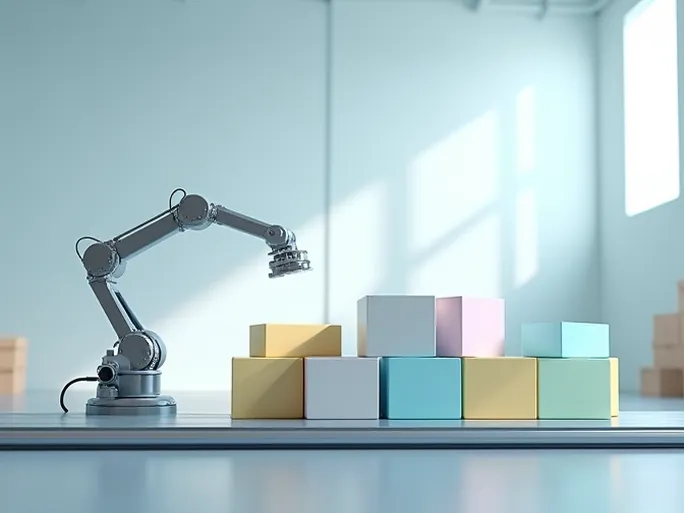

Digital transformation offers the solution. Providers adopting warehouse robotics, IoT sensors, AI-driven analytics, and blockchain tracking can demonstrate transparent, measurable value—transforming transactional relationships into strategic alliances.

Robotics as Workforce Augmentation

Contrary to common fears, automation isn't displacing human workers but enhancing their capabilities. Andy Johnston, GEODIS innovation director, emphasizes that collaborative robots ("cobots") reduce physical strain while boosting productivity.

- Intuitive interfaces with multilingual support can cut training time by 50%

- Performance-based operations see mutual benefits in efficiency gains

- Automation enables safer work environments with consistent social distancing

The Path Forward

As states reopen amid evolving health guidelines, robotics provide operational continuity where human distancing remains essential. The most successful 3PL providers will be those that:

- Integrate digital tools into core operations and culture

- Deliver real-time visibility across supply chains

- Develop predictive capabilities for inventory optimization

- Prioritize workforce safety through automation

The post-pandemic landscape will reward providers who transform not just their operations, but their value proposition—moving from cost-focused vendors to innovation-driven partners shaping the future of logistics.