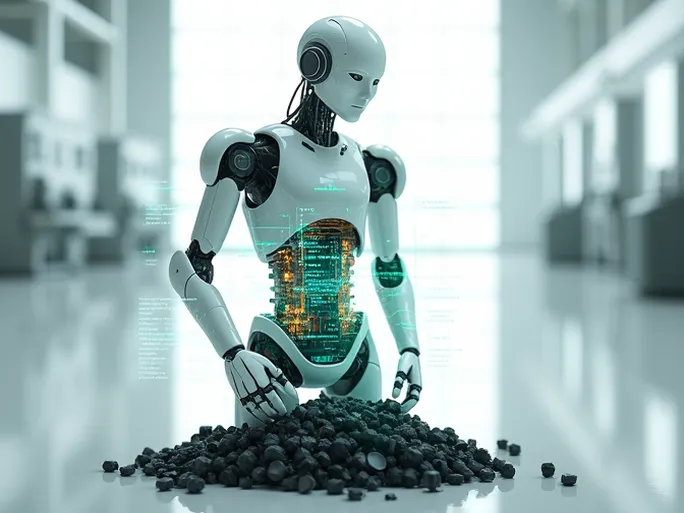

Humanoid robots are no longer a distant dream but are rapidly advancing toward industrial application. What is driving this transformation? The story of two young engineers at Ubtech reveals how Chinese innovators are propelling the development of embodied intelligence, not only realizing personal ambitions but also contributing to the rise of China's smart manufacturing sector.

I. Vision Breakthrough: Overcoming Environmental Challenges

Zeng Yusheng, a visual algorithm engineer at Ubtech, is tasked with giving humanoid robots their "eyes." In industrial settings, particularly at Dongfeng Liuzhou's assembly plant, robots must accurately sort stacked workpieces. Black workpieces, with their light-absorbing surfaces, pose significant challenges to traditional 3D vision systems, as shadows and reflections further complicate position and orientation recognition.

1. The Challenge: Identifying Black Workpieces

Traditional 3D vision systems struggle with black workpieces due to:

- Missing depth data: Black surfaces absorb light, making it difficult for sensors to capture accurate depth information.

- Environmental interference: Shadows and reflections distort visual data, reducing recognition accuracy.

- Orientation detection: The lack of clear feature points makes it hard to determine precise workpiece orientation.

2. The Solution: Data-Driven Model Fusion

To address these challenges, Zeng and his team developed an innovative approach:

- Simulation technology: Generated comprehensive scene data to simulate various lighting conditions and workpiece orientations, providing ample training samples.

- Model fusion: Combined multiple vision models to enhance adaptability in complex environments.

- Custom algorithms: Developed proprietary algorithms to extract surface features and compensate for missing depth data.

3. Results: Precision and Efficiency Gains

The optimized vision solution delivered significant improvements:

- Higher sorting accuracy: Robots can now reliably identify and handle black workpieces, reducing manual intervention.

- Full automation: Achieved end-to-end automated sorting, boosting productivity and cutting costs.

- Environmental robustness: The system performs consistently despite lighting variations and interference.

II. Powering Motion: High-Performance Servo Drives

If vision serves as the robot's "eyes," servo drives function as its "nervous system and power brain," determining joint precision and stability. Xu Changping, a hardware engineer at Ubtech, leads the development of these critical components.

1. Design Challenges: Compact Size, High Torque, Reliability

For the Walker S2 robot, Xu's team faced strict requirements:

- Size constraints: Servo drives needed to be compact for robot flexibility.

- Torque demands: Required substantial power output for industrial tasks.

- Thermal management: Needed to operate stably under prolonged use without overheating.

2. Technical Innovations: Hardware, Structure, and Algorithm Optimization

The team implemented a multi-faceted approach:

- Hardware: Optimized circuit architecture and component selection to balance load capacity and heat generation.

- Structural design: Focused on thermal management, improving heat dissipation paths to reduce temperature rise.

- Algorithm: Used software to dynamically adjust torque distribution across joints, preventing localized overheating.

3. Performance Achievements

The resulting servo drives demonstrated:

- Precision control: Enabled accurate and smooth joint movements.

- Operational stability: Maintained performance under heavy, continuous workloads.

- Enhanced reliability: Extended service life through optimized design and high-quality components.

III. Synergy of Dreams: Personal Growth and Industrial Advancement

The journeys of Zeng and Xu reflect both personal dedication and Ubtech's alignment with national development goals. Their work bridges individual aspirations with industrial needs, creating a harmonious convergence of personal and national progress.

1. Strategic Alignment

National policies provide clear direction for young engineers. As Zeng noted, strategic plans serve as "opportunity maps," guiding technological priorities and resource allocation.

2. Platform Support

Ubtech fosters innovation by offering:

- Cross-disciplinary learning: Engineers like Zeng transitioned from smart cameras to robotics, embracing new challenges.

- Systems thinking: Xu evolved from component-level expertise to holistic product development.

3. Commercial Realization

The upcoming delivery of 500 Walker S2 units in 2025 marks a milestone in bringing humanoid robots from labs to real-world applications, energizing China's smart manufacturing ecosystem.

IV. Conclusion: Charting the Future of Smart Manufacturing

As Xu observed, "Personal goals intersect with national strategy, and national support elevates individual potential." In the era of embodied intelligence, Ubtech continues to empower young engineers, transforming the vision of "robots in every home" into tangible advancements in next-generation productivity and emerging industries. Together, they are writing a new chapter in smart manufacturing through innovation and collaboration.