Have you ever been puzzled by those mysterious codes on ocean bills of lading? GP, HC, HQ, DC, RF, OT... These seemingly simple letter combinations actually represent significant cost differences and shipping strategies. Understanding them not only makes international trade easier but can also save substantial freight costs. Let's demystify these container types.

1. GP: General Purpose Container – The "All-Rounder" of Shipping

GP , standing for General Purpose Container, is designed for ordinary dry cargo. Like a shipping industry "Swiss Army knife," it's suitable for textiles, electronics, daily necessities and other goods that aren't sensitive to pressure or humidity. GP containers feature excellent sealing, moisture-proofing and theft prevention.

The two most common GP sizes are 20-foot (33 cubic meters capacity, 28-ton max load) and 40-foot (67 cubic meters, 26-ton max load). Choice depends on cargo volume and weight.

Freight rates: Shanghai to Los Angeles routes show 20ft GP containers costing $3000-5000 in peak season (Q4) and $1000-2000 in off-season. Rates fluctuate based on market demand, fuel prices and seasonal factors.

Pros: High versatility and lower costs. Limitations: Height restrictions for tall cargo.

2. HC/HQ: High-Cube Container – The Volume Champion

HC (High-Cube) or HQ containers are about 30cm taller than standard GP containers. This seemingly small difference increases capacity significantly - a 40ft HC offers 76 cubic meters versus 67 for standard GP.

High-cubes are ideal for bulky items like furniture or foam products, allowing more cargo per container and lowering per-unit shipping costs.

Freight rates: Shanghai-LA 40ft HC containers cost $4000-6000 (peak) or $1500-3000 (off-season). While slightly pricier than GP, the greater capacity often provides better value.

Pros: Superior volume efficiency. Limitations: Potential clearance issues with low bridges or tunnels in inland transport.

3. DC: Dry Container – Emphasizing "Dry" Conditions

DC (Dry Container) is essentially identical to GP containers in function, both designed for ordinary dry goods. The terminology difference mainly reflects regional or corporate preferences rather than technical specifications.

Freight rates: Identical to GP container pricing.

4. RF: Reefer Container – The "Mobile Refrigerator"

RF (Reefer Container) maintains specific temperatures (-30°C to 30°C) for perishables like fruits, meat, seafood or pharmaceuticals. These specialized containers feature built-in refrigeration systems.

Freight rates: Qingdao-Tokyo 20ft RF containers cost $5000-8000 (peak) or $3000-5000 (off-season) - several times pricier than dry containers.

Key considerations: Cargo must be pre-chilled before loading, with continuous temperature monitoring during transit. Equipment requires regular maintenance to prevent spoilage.

5. OT: Open-Top Container – Solution for Oversized Cargo

OT (Open-Top) containers feature removable tops or tarpaulins for loading tall, heavy items like machinery, steel or timber. The open design facilitates crane loading of awkwardly shaped cargo.

Freight rates: Shanghai-Rotterdam 40ft OT containers cost $5000-7000 (peak) or $2000-4000 (off-season). Higher pricing reflects specialized handling requirements.

Key considerations: While offering loading flexibility, open tops expose cargo to weather risks, requiring proper securing and waterproof covering.

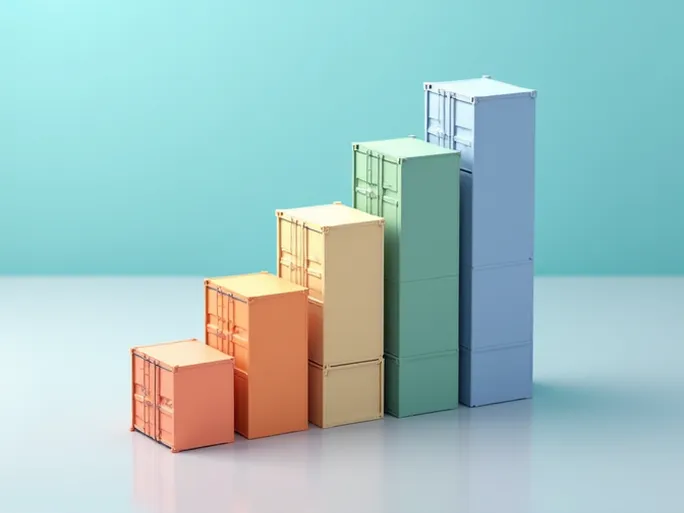

6. Container Selection: Strategic Choices for Cost Efficiency

Selecting appropriate container types is crucial for cargo safety, cost control and shipping efficiency in international trade. Each container type serves specific purposes:

- GP/DC: General dry goods

- HC/HQ: Volume-optimized shipments

- RF: Temperature-sensitive items

- OT: Oversized or heavy cargo

Decision factors should include cargo characteristics, shipping distance, costs and destination infrastructure.

7. Conclusion: Mastering Container Knowledge for Global Trade

Understanding shipping container codes represents fundamental knowledge for international trade professionals. These terms appear throughout booking, loading and transportation processes. Proper container selection prevents cargo damage and unnecessary costs while optimizing shipping efficiency.

As global trade evolves and cargo types diversify, continuous learning about container specifications becomes increasingly important for maintaining competitive advantage in international markets.