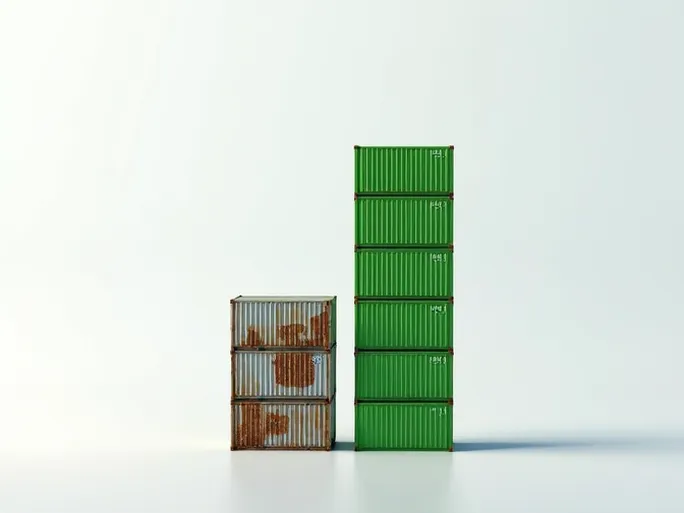

Container shortages, soaring freight rates, and limited vessel space have become persistent challenges in global trade, forcing exporters to reevaluate their logistics strategies. As traditional shipping models show their limitations, a more autonomous and cost-effective solution—Shipper's Own Containers (SOC)—is emerging as a strategic advantage for businesses looking to optimize their supply chains.

Understanding SOC Containers

SOC (Shipper's Own Container) refers to standardized shipping containers that are owned or leased by the cargo owner rather than the carrier. This fundamental ownership distinction creates significant differences in cost structures, loading priorities, and destination port operations compared to Carrier's Own Containers (COC).

Types of SOC Containers

Exporters can choose from three primary SOC options, each with distinct advantages:

- New containers: Offer superior quality and longest lifespan, though with higher acquisition costs. Ideal for shipments requiring maximum security and reliability.

- Used containers: Provide cost savings but require thorough inspection for structural integrity. Containers with 60-80% remaining lifespan typically offer the best value.

- Leased containers: Deliver maximum flexibility without long-term ownership commitments, particularly suitable for irregular shipping needs.

Current market data shows a 20GP new container in East China ports costs $1,800-$2,200, while used containers (60-80% condition) range from $800-$1,200. Short-term leasing averages $5-$8 per day. Businesses with stable monthly volumes exceeding 50TEU can achieve cost reductions below 60% of COC models through strategic SOC implementation.

Strategic Applications of SOC

SOC containers demonstrate particular value in several critical scenarios:

Peak Season Capacity Assurance

During the 2023 peak season (August-October) on the US West Coast route, Los Angeles port reported COC empty container turnaround times extending to 12 days. One furniture exporter secured significant advantages by maintaining a fleet of 50 40HQ SOC containers:

- Priority loading status reduced booking confirmation times by 2-3 business days

- Negotiated SOC rates achieved 18-22% discounts versus COC market prices

- Loading rejection rates dropped from 15% to below 3%

Destination Port Cost Reduction

Certain Southeast Asian ports impose substantial COC detention charges. A chemical exporter shipping to Indonesia reduced per-container destination costs from $450 to $180 using SOC, generating annual savings exceeding $320,000 for 100TEU quarterly volumes.

Specialized Cargo Solutions

SOC enables customized solutions for unique shipping requirements:

- Heavy cargo: Modified SOC containers can accommodate 28-ton loads versus standard 24-ton COC limits

- Temperature-sensitive goods: Self-managed refrigerated SOC units offer 30%+ cost savings and precise climate control

Cost Structure and Management

Effective SOC implementation requires understanding its complete cost components:

- Container acquisition/leasing expenses

- Maintenance and repair costs

- Empty container repositioning

- Administrative overhead

Strategic container sourcing approaches include:

- Purchasing: Economical when annual rotations exceed 6 cycles

- Leasing: Preferable for short-term or one-way shipments

- Condition management: Implement ISO 1496-1 inspection standards to minimize carrier rejections

Operational Considerations

The SOC workflow differs significantly from COC processes:

- Container procurement

- Specialized booking notation

- Customs documentation

- Loading and securing

- Transportation monitoring

- Destination clearance

- Container recovery or reuse

Critical documentation requirements include explicit SOC declarations in booking notes and specialized bill of lading clauses to prevent container ownership disputes.

Risk Management Framework

While offering substantial benefits, SOC introduces unique risks requiring mitigation strategies:

- Container damage/loss: Comprehensive marine insurance coverage

- Detention charges: Pre-negotiated return agreements with local agents

- Port restrictions: Advanced verification of destination requirements

- Repositioning: Optimized container rotation planning

Proactive measures include GPS tracking systems and legal preparedness for dispute resolution, with successful challenge rates exceeding 60% in certain jurisdictions.

Strategic Implementation Analysis

SOC represents a dual-edged solution—delivering 15-30% cost savings, 40%+ loading priority improvements, and 90%+ specialized cargo compatibility, while requiring substantial capital commitments and management resources.

Businesses exceeding 500TEU annual volumes with stable shipping patterns and adequate logistics budgets stand to gain most from SOC adoption. Smaller enterprises may benefit from collaborative container-sharing models. As digital container management platforms mature, SOC is positioned to become the preferred solution for cross-border e-commerce and commodity shipping within 3-5 years.

In today's volatile shipping markets, SOC mastery provides more than cost reduction—it represents a fundamental shift toward supply chain autonomy and competitive differentiation.