Across China's manufacturing landscape, artificial intelligence is rewriting the rules of traditional industries. In Wuhu, a footwear team leveraged AI to boost annual sales to 150 million yuan. In Dongguan, a jewelry factory run by post-90s entrepreneurs climbed to the top of its category rankings in just 15 days using AI tools. In Shenzhen, a 3C accessories manufacturer generated over 11 million yuan in sales within 38 days of launching new products through AI-powered flexible supply chains.

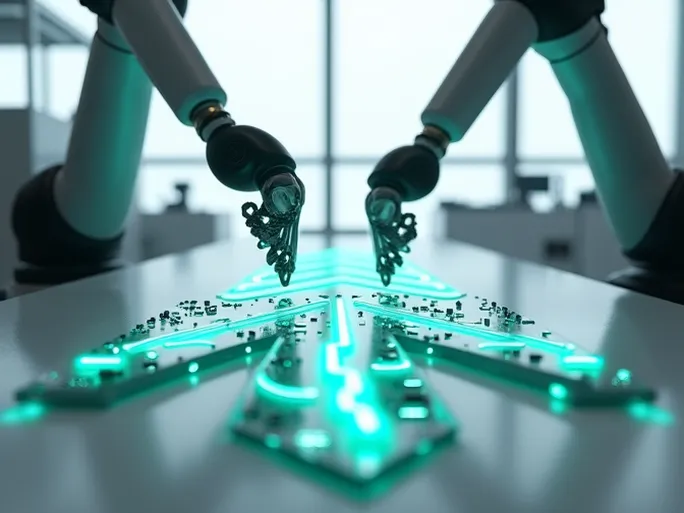

These success stories signal the accelerated arrival of what industry observers call the "AI symbiosis" era, where a new generation of factory owners is driving industrial transformation through technological adoption.

The AI Adoption Roadmap

The 2025 China Industrial Belt Development Trends Report projects distinct stages of AI implementation:

2024-2025 (AI Augmentation Phase): AI serves as efficiency tools within existing workflows.

2026-2027 (AI Symbiosis Phase): Deep integration with core business operations.

2028 Onward (AI Native Phase): Autonomous AI-driven decision-making and innovation.

Challenges in B2B Transformation

Despite the potential, the transition from digital to intelligent operations faces significant hurdles:

1. Fragmented Supply Chains: Numerous small-to-medium factories with varying capabilities struggle to form efficient systems.

2. Customization Demands: Standardized products increasingly fail to meet specialized requirements.

3. Complex Transactions: Lengthy decision chains from sourcing to fulfillment reduce efficiency.

4. Knowledge Retention: Overreliance on individual expertise prevents systematic knowledge transfer.

AI2B: The Transformation Engine

AI-powered business solutions (AI2B) are emerging as critical infrastructure for industrial upgrading, shifting traditional factories from experience-based operations to user-centric, AI-driven models. This transformation affects both operational logic and value distribution mechanisms.

Younger-generation factory owners demonstrate particularly high "AI density," actively applying artificial intelligence across design, production, and marketing. Platform data shows over 290,000 merchants daily utilizing AI tools among 1 million registered businesses, with adoption rates steadily climbing.

Regional Adoption Patterns

Geographic analysis reveals distinct development trajectories:

Eastern China (Guangdong, Zhejiang, Jiangsu): Transitioning from manufacturing hubs to demand-processing centers.

Central China (Henan, Anhui, Hubei, Hunan, Jiangxi): Exhibiting the fastest digital growth with specialized enterprises proliferating.

Western China (Sichuan, Chongqing, Shaanxi): Expanding digital coverage with AI-accelerated niche market penetration.

Yiwu leads national AI adoption metrics, followed by manufacturing powerhouses Guangzhou, Shenzhen, Dongguan, and Wenzhou - collectively forming China's vanguard of industrial intelligence.

As AI becomes deeply embedded across industrial ecosystems, early adopters stand to gain significant competitive advantages through enhanced efficiency, flexible supply chains, and precise market insights - ultimately redefining B2B commerce in the coming decade.